Work processes can release airborne contaminants such as dust, gases, fumes, vapours, or mists, which pose health and safety risks. Starting from 1 December 2026, Australia will enforce updated Workplace Exposure Limits (WEL) for these contaminants. This revision, driven by extensive review and consultation, includes renaming and refining the standards previously known as Workplace Exposure Standards (WES) to highlight their role as strict limits that must not be exceeded. This alignment with international standards reflects Australia’s commitment to global best practices.

Integrating the new WEL list into WHS laws nationwide will impact all sectors across the Commonwealth, states, and territories. During the transition period, PCBUs must adhere to current WES limits to maintain safe levels of airborne contaminants.

Important changes ahead for workplace exposure limits.

Safe Work Australia (SWA) is actively developing guidance and support materials to facilitate the transition to the new Workplace Exposure Limits. These resources will be available throughout the transitional period and beyond, ensuring that PCBUs are well-equipped to comply with the new standards.

In response to stakeholder feedback, WHS ministers have directed SWA to conduct additional impact analysis for proposed changes to the WES for nine specific chemicals:

- Benzene

- Chlorine

- Copper (fumes, dusts, and mists)

- Formaldehyde

- Hydrogen cyanide

- Hydrogen sulphide

- Nitrogen dioxide

- Respirable crystalline silica

- Titanium dioxide

This detailed impact analysis is currently ongoing. Until it is completed and WHS ministers make a final decision, the WEL for these chemicals will remain the same as those listed in the existing WES. This cautious approach ensures that any changes to exposure limits are based on thorough research and consideration of potential impacts on health and industry.

Recommended actions for compliance.

As a PCBU, it is crucial to prepare for the adoption of the new Workplace Exposure Limits (WEL) during the transition period ending on 30 November 2026. To ensure compliance:

- Start by reviewing the WEL list to determine which airborne contaminants are present in your workplace and the new limits effective from 1 December 2026.

- Next, ensure that no worker is exposed to airborne concentrations exceeding the WEL. If there is uncertainty about whether your workplace meets these limits, conduct air monitoring to assess exposure levels accurately. You can request Fanquip team to do it

- Implement appropriate controls to ensure that exposure does not exceed the WEL. Aim to eliminate airborne contaminants where possible. If elimination is not reasonably practicable, minimise the risk by following the hierarchy of controls. Regularly review and verify the effectiveness of your control measures to ensure they function as intended.

By proactively identifying, assessing, and controlling airborne contaminant hazards, PCBUs can ensure a safe and compliant workplace ahead of the new WEL implementation.

Common ventilation systems to control airborne contaminants.

The vast product portfolio of Fanquip is designed to capture airborne contaminants and supply fresh air to working facilities. We have identified the most common fans used by our customers across various industries.

Roof and Wall Exhaust Fans.

Fanquip excels in providing robust ventilation solutions tailored for industries, featuring a diverse range of Roof fans, Wall fans and relief vents essential for refreshing indoor environments with clean outdoor air. This critical ventilation process effectively manages indoor climate conditions, purifies air quality, and maintains balanced moisture levels, significantly reducing the risk of mould growth and harmful chemical buildup. Our industrial roof and wall fans stand out as top choices in the exhaust fan lineup due to their straightforward installation, quiet operation and versatility across diverse industrial facilities. Specifically engineered to extract air filled with moisture, odours, and particles from industrial settings, these fans play a crucial role in enhancing indoor air quality by eliminating pollutants and excessive humidity from commercial premises.

Fume Extractors.

Among our fume extractor range, the Mobile Fume Extractor stands out as the preferred choice for operations needing efficient at-source extraction of fumes. It is particularly effective in capturing airborne particles like welding fumes, grinding dust, dry dust, and soldering fumes right at their origin. Engineered for versatility, this extractor features a flexible arm and sturdy wheels, allowing easy movement and precise positioning throughout your facility. It boasts a two-stage filtration system with a pre-filter and HEPA filter, ensuring thorough air purification

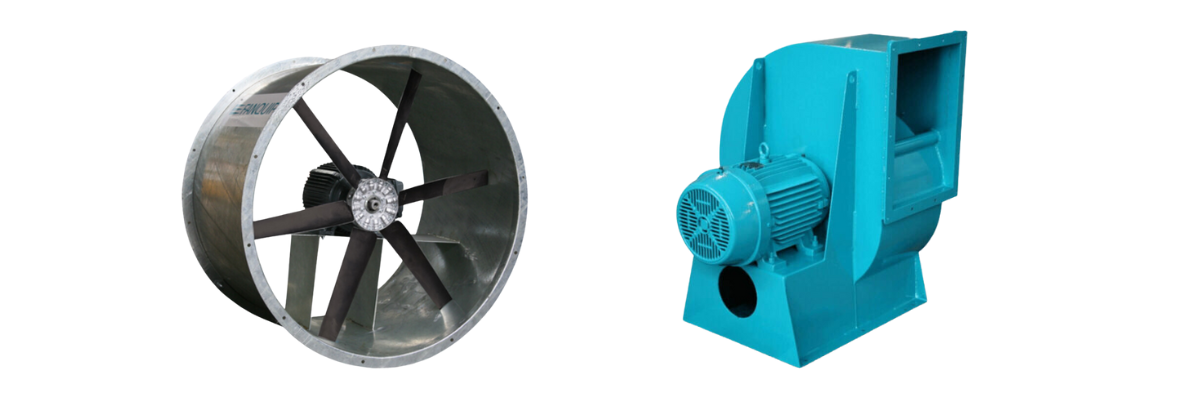

Axial and Centrifugal Fans.

Axial and centrifugal fans, often referred to interchangeably as industrial blowers, are essential for facilities that require efficient air movement over long distances. Axial fans propel air directly ahead using blades, making them ideal for applications needing linear airflow. They are widely used in industrial settings like factories, warehouses, and mining operations to ensure effective ventilation and air circulation. In contrast, Centrifugal fans are more powerful and capable of moving air at higher velocities. They utilise centrifugal force to draw air into the blades and discharge it at a 90-degree angle, creating a swirling airflow. These fans are highly efficient in handling gases and materials, making them crucial for air conveyor systems, materials handling processes, and various industrial applications such as filter flushing, gas boosting, aeration, as well as cooling and drying processes.

Ensure compliance with new exposure limits.

At Fanquip, we prioritise maintaining a clean and safe working environment. Our exhaust fans and specialised fume extractors cater to diverse industrial needs, helping you meet the new exposure limits. Share your requirements at [email protected] or call 1300 224 308 and our team will suggest a suitable fan for your needs.