The Paper Mill ABC Tissue are most known for their range of Quilton toilet tissue paper, which is commonly found in homes across Australia.

The company have been a customer of ours since 2015, after they become the first company to own and install a tissue making machine in Sydney.

ABC Tissue approached Fanquip due to our expertise and experience working with paper mills. We have witnessed first-hand the conditions and day to day operational problems paper mills can face without adequate ventilation. Some of the challenges paper mills can face includes corrosion, particulate dust, and odours in the air. These issues can impact the health of employees, but also damage production machinery leading to downtime and maintenance.

Therefore, it was imperative that ABC machine implemented a robust ventilation solution before beginning their tissue production. Fanquip provided ABC tissue with a custom designed extraction fan system, made for their unique situation.

The solution:

We provided 6 x vertical discharge roof fans.

These were customised with the following specifications:

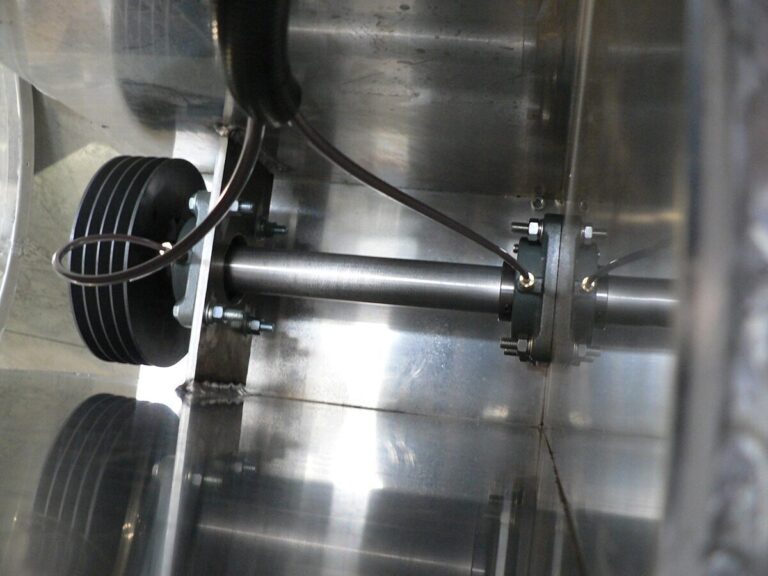

- E.M.D.S. – Encapsulating Motor Drive System – to protect motor completely from particle laden airstream – motor is vented to external side to minimise operating temperature differential (this is a key feature utilised in the paper production industry)

- Complete aluminium construction for longevity and corrosion resistance

- Large person access panels to allow ease of cleaning and maintenance

- Incorporated external weather proofing kit to stop ingress to production area

- High air volume with minimised pressure loss to maintain positive removal of heat & steam

Specifications:

- Model No. 3-15123SP-ABC

- 1520mm diameter

- 7.5kw, 425v, 50Hz, 3phase, Class H Motors

- Aluminium/FRGRP Impeller

- HD Series Construction

- Aluminium construction

- E.M.D.S. – Encapsulated Motor Drive System