The Importance of Ventilation in Meat Processing

Ventilation plays a crucial role in maintaining hygiene standards in meat processing facilities. Adequate airflow helps to control temperature and humidity levels, which are vital for preserving meat quality and ensuring a clean environment. Proper ventilation systems can effectively prevent the buildup of harmful bacteria, reduce condensation, and eliminate unpleasant odors.

In meat processing operations, maintaining a controlled environment is essential for both safety and product quality. Effective ventilation systems contribute to a healthier work environment by reducing airborne contaminants and minimizing the risk of cross-contamination. This ensures that the products meet stringent hygiene standards and regulatory requirements.

Challenges Faced by Meat Processing Facilities

Meat processing facilities often encounter several challenges related to maintaining hygiene and temperature control. One major issue is condensation, which can lead to rust formation on equipment and surfaces, posing a significant hygiene risk. Additionally, insect intrusion and temperature fluctuations can compromise the quality and safety of the meat products.

Another challenge is the extraction of steam generated during nighttime cleaning operations. The steam often contains chemical components from cleaning agents, which can complicate the extraction process and potentially damage ventilation systems over time. Addressing these challenges requires innovative solutions that can effectively manage airflow and maintain a controlled environment.

Air Curtains: Barrier between indoor and outdoor spaces

Air curtains, also known as air doors, offer an effective solution for maintaining hygiene in meat processing facilities. These electric-fan-powered devices create an invisible barrier by blowing a controlled stream of air across an opening. This barrier helps to separate indoor and outdoor environments without obstructing access, thereby preventing dust, odors, and insects from entering the facility.

In addition to blocking contaminants, air curtains are highly efficient in retaining cool air during summer and restricting warm air from escaping during winter. This helps to maintain stable indoor temperatures, which is critical for meat processing operations. Air curtains are particularly effective for walk-in refrigerators, preventing cold air loss and ensuring optimal storage conditions.

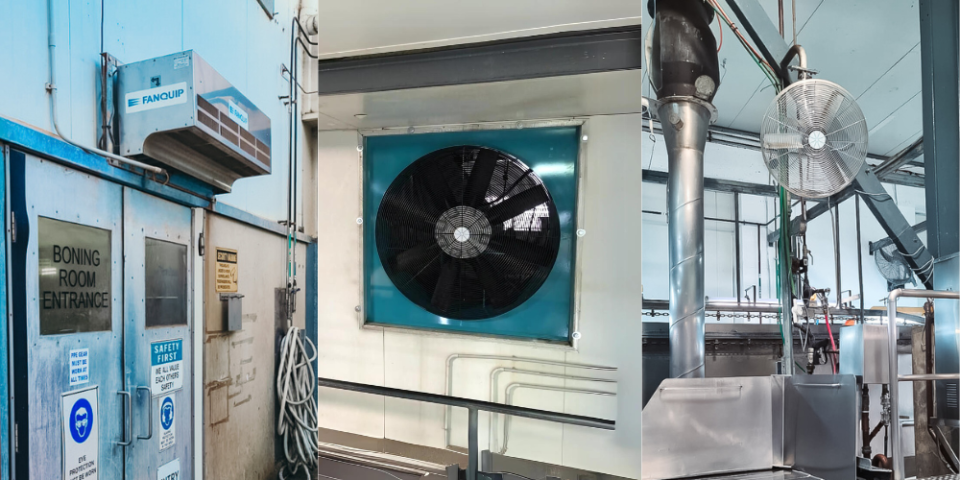

Wall Plate Exhaust Fans: Air supply and extraction

Wall plate exhaust fans are essential for improving air quality in meat processing facilities. These versatile devices can function as both exhaust and air supply fans, effectively removing heat, smoke, dust, and other airborne particles from large, enclosed areas. By reducing excess moisture, exhaust fans help mitigate the risks of fungal growth and equipment damage.

In the marshalling area of the facility, installing exhaust fans is crucial for extracting the steam generated during cleaning operations. Despite the challenges posed by the chemical components in the steam, advanced exhaust fan systems can be designed to handle such conditions, ensuring reliable and efficient ventilation.

Air Circulators: Consistent airflow throughout the facility

Air circulators play a vital role in maintaining consistent airflow throughout meat processing facilities. These devices help distribute air evenly, preventing hotspots and ensuring a uniform temperature across the workspace. By enhancing airflow, air circulators contribute to a healthier and more comfortable working environment, reducing the risk of condensation and rust formation.

In addition to improving air quality, air circulators can also help in energy conservation. By promoting efficient air movement, they reduce the need for excessive heating or cooling, leading to lower energy consumption and operational costs. This aligns with the company’s commitment to environmental sustainability and operational efficiency.

Case Study: Ensuring hygiene in meat processing operations with ventilation systems.

A leading vertically integrated beef and veal processing operation in Australia faced significant challenges with ventilation in their state-of-the-art export facility. Issues such as condensation, rust on equipment, insect intrusion, and temperature fluctuations were compromising hygiene standards and product quality.

To address these challenges, the company implemented a combination of air curtains, wall plate exhaust fans, and air circulators. The air curtains effectively blocked insects and dust from entering the facility, while the exhaust fans efficiently extracted steam and airborne particles. The air circulators ensured consistent airflow and temperature control, significantly improving the overall hygiene and safety of the meat processing operations. This comprehensive approach not only enhanced product quality but also reinforced the company’s dedication to sustainability and environmental responsibility.