Running laundry machines every two days produces around 440kg of CO2e. Clothes dryers are among the top appliances releasing carbon monoxide, posing serious health risks if not properly managed.

If you’re in the commercial laundry services industry, investing in an effective ventilation strategy is crucial.

What is carbon monoxide?

Carbon monoxide is a colorless, odorless, and combustible gas that poses serious health risks, including confusion, dizziness, and even death from poisoning and oxygen deprivation. In the laundry industry, it’s produced when burning propane, a common fossil fuel used to heat washing machines and dryers. Additionally, the lint generated in laundry rooms during drying is primarily carbon-based, adding to the risk.

Why is there carbon monoxide in a laundry facility?

- Combustion Equipment Emissions: Commercial laundry equipment like gas-powered dryers and water heaters can emit carbon monoxide if there’s poor air supply, burner malfunctions, or clogged exhaust systems.

- Poor Ventilation Systems: Inefficient or malfunctioning ventilation systems, like blocked filtration ducts, reduce air quality and allow CO to accumulate in enclosed laundry rooms.

- Interference with Ventilation: Obstructions like misplaced equipment can block ventilation systems, leading to localised carbon monoxide buildup.

- Leakage: Carbon monoxide can leak into the facility from areas like parking garages or boiler rooms, compromising air quality.

- Improper Maintenance: Neglecting maintenance of combustion equipment and sensors can result in undetected leaks, increasing health hazards.

How to mitigate carbon monoxide in the laundry industry?

Implementing proper ventilation solutions is key to maintaining safe air quality in your facility. Here’s why it’s important:

- Reduces humidity, improving working conditions and preventing mold.

- Regulates temperature, preventing stagnant air and enhancing energy efficiency.

- Extracts contaminants like lint and gases, ensuring worker safety.

- Supports faster drying through improved airflow.

- Cools down laundry machines and equipment, preventing overheating.

Planning a solid ventilation strategy ensures compliance with laundry requirements and maintains a safe environment.

Top ventilation solutions for laundry facilities

Centrifugal Fans

A centrifugal fan uses curved blades around a central hub to create high-pressure airflow, ideal for effective ventilation and air conditioning in laundry rooms.

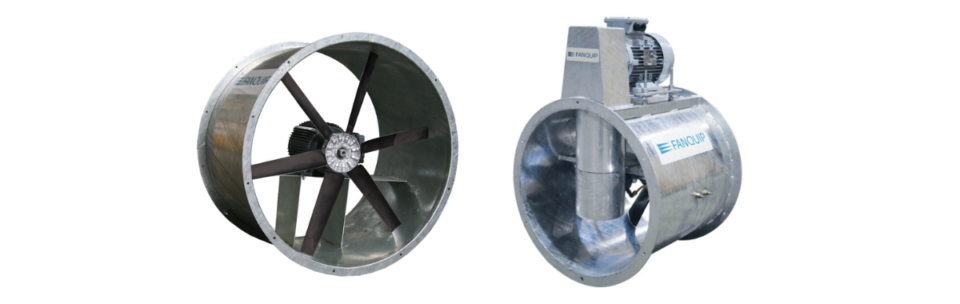

Axial Flow Fans

Designed to pull air parallel to the fan’s axis, axial flow fans are perfect for circulating air in large open spaces, providing general ventilation and cooling equipment.

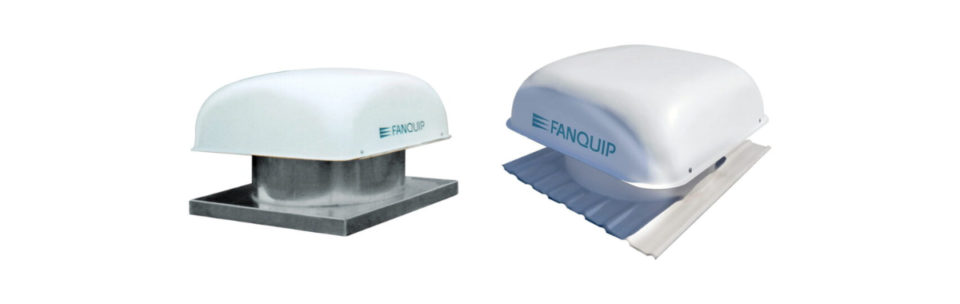

Hooded Roof Fans

As an industrial exhaust fan, hooded roof fans expel air and contaminants from inside the facility, while its protective hood shields the motor from outdoor elements.

Commercial laundry ventilation requirements

Ensuring your facility meets the latest ventilation requirements is essential for safety and efficiency. For detailed information on specific commercial laundry requirements, check out this guide on commercial laundry ventilation.

Choose Fanquip for laundry facility ventilation

Proper ventilation systems are essential for operating a safe laundry facility. Without adequate airflow, carbon monoxide can accumulate, leading to severe health risks, including illness, explosions, or fatalities.

Need assistance with your ventilation requirements? Contact the Fanquip team. Our experts will help you design an efficient, compliant ventilation strategy tailored to your facility’s needs.