Washing and drying a load of laundry every 2 days creates around 440kg of CO2e, and clothes dryers are among the top appliances that cause carbon monoxide release.

If you’re working in the laundromat industry, you must invest in an adequate ventilation strategy.

What is carbon monoxide?

Carbon monoxide is a colourless, odourless gas that can be dangerous when inhaled in large quantities. It is combustible and so presents the risk of explosion upon ignition. If inhaled, it can cause confusion, lightheadedness, and death due to poisoning and oxygen deprivation. It is produced in the laundry industry when propane, a popular fossil fuel, is burnt to produce heat and energy. The laundry industry is carbon-based, meaning the lint produced during the drying process is primarily carbon lint.

Why is there carbon monoxide in a laundry facility?

There are several reasons why carbon monoxide removal is needed in laundry facilities:

- Combustion equipment emissions – carbon monoxide can be present in laundry facilities due to commercial laundry equipment like dryers powered by gas fires. Gas water heaters, too, can contribute carbon monoxide to your facility. If there is poor air supply, a burner malfunction, or the exhaust system becomes clogged with lint, CO will be released during combustion.

- Poor ventilation systems – inefficient, malfunctioning ventilation systems like blocked filtration ducts and generally poor airflow can cause CO to accumulate within the laundry facility. If the space is enclosed, then the CO will not be able to dissipate properly.

- Interference with ventilation – if obstructions such as equipment in the way of your ventilation system, carbon monoxide, leading to localised pockets of CO buildup.

- Leakage – when combustion occurs in other areas of the laundry facility, such as parking carriages and boiler rooms, there can be leakage into the facility causing unclean air.

- Improper maintenance – if combustion equipment like sensors are not properly monitored and maintained, this can cause undetected leaks to persist, causing potential harm to occupants of the laundry facility.

How to mitigate carbon monoxide in the laundry industry?

If you’re operating a laundry facility, you must invest in ventilation solutions to mitigate the presence of carbon monoxide. Here are some of the reasons why proper ventilation is essential:

- It mitigates humidity in the air, providing more comfortable working conditions for laundry staff and preventing dampness and mould.

- It regulates the temperature in the facility, ensuring no stagnant air pockets of stratification. Stratification can make your heating and cooling systems less efficient.

- It extracts contaminants, such as lint and harmful gases, to ensure worker safety.

- It facilitates drying by promoting evaporative cooling processes.

- It helps to cool down laundry facility equipment, extracting heat that accumulates in the surrounding air.

Planning a ventilation strategy is essential to provide a compliant and efficient laundry facility. Here are some of the top commercial laundry solutions to assist you in ventilation planning.

Centrifugal Fans

A Centrifugal Fan is an air circulation mechanism with curved blades around a central hub. It directs incoming airflow towards the perimeter of the fan housing to create high air pressure. This solution is perfect for providing ventilation and air conditioning for laundry facilities.

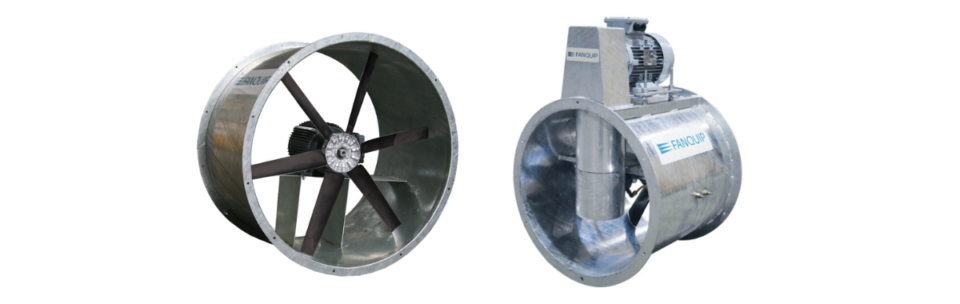

Axial Flow Fans

An Axial Flow Fan provides airflow by pulling air parallel to the fan’s axis and creating a linear air pathway. The blades exert force in the direction of the fan’s rotation to propel air along the same axis. They are handy for circulating air in large open spaces, providing general ventilation, and cooling equipment.

Hooded Roof Fans

A Hooded Roof Fan is an exhaust fan. It has a protective hood that shields the motor from exposure to weather elements and attaches to a building’s roof to expel air and contaminants that can build up inside a facility.

Choose Fanquip for laundry facility ventilation

Ventilation is at the heart of operating a safe laundry facility. If you don’t have a steady airflow, carbon monoxide can build up, presenting the risk of illness, explosions, and even fatalities on site.

Need help planning your ventilation strategy? Contact the Fanquip team. Our experts can help you meet ventilation requirements for your facility’s size, ensuring total compliance with industry regulations.