Each year, the Australian Government Department of Agriculture, Fisheries and Forestry operates the National Residue Survey (NRS) which monitors pesticide and vetinary medicine residue in food products. This survey verifies that our agricultural and seafood industries produce quality food that doesn’t contain contaminants like chemicals, pesticide residues or microorganisms, inline with legislation and guidelines.

In the National Residue Survey for 2021-22, 6,586-grain samples were collected. The survey found that 99.2% of the grain samples complied with Australian standards for residue.

To maintain compliance and competitive advantage in the agricultural industry, you must prevent contamination – and ventilation is the optimal strategy.

Keep reading as we explore and discuss ventilation in agriculture and why grain drying fans are so crucial for grain drying processes.

Why do you need industrial fans in agriculture?

Fans serve many functions in the agricultural industry. Let’s discuss the applications and benefits of industrial fans in agriculture to highlight ROI potential.

Optimal growing conditions for crops

Industrial fans regulate the temperature in greenhouses and enclosed crop-growing or grain dryer areas.

They provide air circulation, which prevents hot or cold air pockets from forming to encourage the exchange of gases and even temperatures throughout the greenhouse or growing facility. The even distribution of CO2 is extremely beneficial for plant photosynthesis.

These two functions of industrial fans support plant growth, providing optimal growing conditions.

Reducing the risk of crop loss due to diseases

Industrial fans are instrumental to airflow, which helps to reduce moisture caused by humidity. Without moisture regulation, fungi and bacteria would be rife in your growing facility, increasing crop loss margins.

The air movement facilitates evaporation to reduce moisture while discouraging the spread of pathogens and pests that would typically thrive in stagnant air. Additionally, industrial fans prevent disease development by facilitating plant drying following irrigation.

Improving air quality in agricultural areas

Air quality is essential for plant growth and health. With industrial fans, you can exhaust stale air and introduce fresh air into your growing facility. Fresh air will reduce the risk of fungi and bacteria growing in the facility while reducing odours and pollutants.

Animal waste can quickly build up in agricultural settings, emitting ammonia and methane. Industrial fans help to exhaust these pollutants from the atmosphere to ensure plant health. The industrial fan will also effectively remove airborne particles, dust, and allergens to reduce contamination of grain products.

Improving air quality will improve the quality and growth of your crops and create a more pleasant and comfortable working atmosphere for your workers.

Airflow requirements for grain and wheat drying

What should the airflow exchange rate be for your crop facilities? In a greenhouse setting, there should be a minimum of 30 air exchanges each hour. However, you should aim for around 60 air changes daily to optimise plant growth and minimise contamination.

For grain drying processes, you should ensure the airflow rate is between 15-25 litres of air per second per tonne of grain. The ideal grain temperature is under 23 degrees Celsius to maintain quality and prevent insect and pathogen contamination. By implementing ventilation solutions, you can ensure even temperature distribution to maximise the efficiency of your heating and cooling solutions.

Top agricultural fans for grain and garlic drying

Now that we have discussed the importance of industrial fans in agriculture let’s explore the best crop-drying fans for your grain and garlic drying processes.

Axial fans

A direct-drive axial fan is the perfect airflow management system for grain and garlic. They have adjustable speed controls that allow you to ensure the optimal conditions for the crop you’re storing. You can’t beat axial fans for versatility if you’re seeking a ventilation solution for lower-pressure or mixed-pressure applications, such as potato or bulb stores.

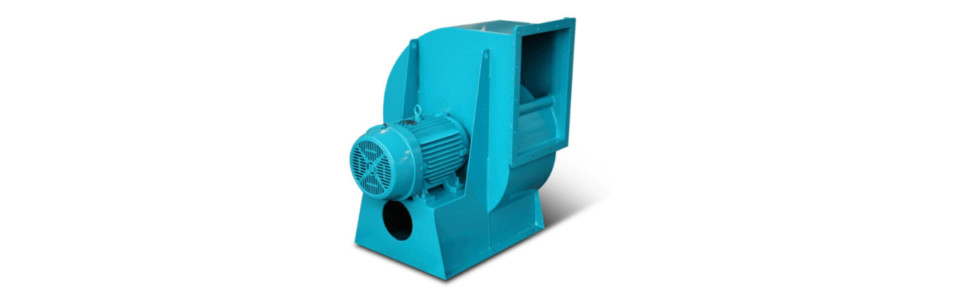

Centrifugal fans

A centrifugal fan is the top recommended solution for managing moisture in an agricultural facility. You can easily adopt a centrifugal fan to manage humidity in high-pressure applications such as grain and seed stores. You might also consider using a multi-stage axial fan in this context, but ultimately the decision rests on the scale of your needs. A multi-stage axial fan might be the best choice if you have low power availability.

Heater fans

Heater fans include the following specifications that make them apt for grain drying processes:

- High heat output – provides efficient and effective drying with faster moisture removal, minimising the potential for grain spoilage.

- Adjustable temperature settings – you can use the temperature control settings to maintain the optimal drying temperature, ensuring grain quality and reducing the risk of over-drying.

- Safe ignition and flame monitoring – heater fans have reliable ignition systems like an electronic or direct spark, accompanied by flame monitoring sensors. These safety mechanisms protect from fire hazards, detecting and monitoring the flame.

Fanquip: Your top choice for industrial fans

Agricultural processes require proper ventilation to prevent compromised products and facilitate crop growth. Industrial fans have many applications in the agricultural industry and can be extremely helpful in promoting efficient grain-drying processes.

Are you using ventilation to increase your output without compromising quality? Speak to our experts at Fanquip. We have in-depth knowledge of agricultural fan applications and can recommend the best solution for your facility’s specifications.