Maintain environmental conditions by keeping your industrial facility, warehouse or workshop adequately ventilated. According to recent studies at Sydney University, there’s a rapid deterioration of employee performance if workplace temperatures rise outside of a set range [1]. Mitigate industrial risks by installing ventilation and cooling solutions to maintain optimal temperatures, airflow, and humidity levels.

According to SafeWork, the temperature should be maintained within a range of 20-26 degrees for most tasks, however, it can be lower for higher levels of physical activity [2]. To prevent air stagnation, the air velocity needs to be set in the range of 0.1-0.2m per second. Humidity levels should sit between 40% and 70%, as higher levels of moisture can cause heat-related illnesses whereas low humidity could limit the respiratory health of personnel.

Cooling, air supply and ventilation considerations:

- Temperature

- Air movement

- Humidity levels

Understanding and implementing a solution based on these air quality figures can be challenging. Talk to a Fanquip ventilation engineer or technical sales expert for advice prior to installing your turn-key ventilation solution.

Industrial cooling & ventilation considerations.

Breathing in stagnant or stale air can lead to potential health implications such as skin irritations, headaches and fatigue [3]. Inadequate ventilation is particularly concerning for employees with underlying health conditions like asthma, allergies, or respiratory problems. An effective ventilation system allows hot air to be extracted from your industrial facility, keeping the space cool, clean and comfortable.

Airborne dust and fumes are a reality for some industrial workplaces. Employees within industries such as manufacturing, vehicle repair shops, bakeries, warehouses, or workshops are particularly vulnerable to the potentially harmful effects of fumes, dust, gases and airborne contaminants. It’s crucial that businesses take the necessary precautions by installing ventilation and cooling systems and implementing adequate processes and procedures.

Industrial cooling solutions.

Industrial fans can help ensure your working environment fits within these thresholds, maintaining productivity without issue, and optimising human performance. Fanquip offers many industrial fans, ventilation, and cooling systems to help achieve and maintain thermal comfort in indoor work environments.

Industrial Mancooler.

Industrial strength Mancoolers are the perfect solution for cooling high-traffic areas, with a powerful air flow volume. Fanquip’s selection of Mancoolers offer longevity and durability, helping to reduce perceived indoor temperatures.

Australian-made with a heavy-duty frame and large-diameter wheels, Mancoolers are designed for industrial facilities and are suitable for various applications, including construction, manufacturing, and mining. Optional extras include hazardous location rating, ceiling or mount application and hydromisting kits for fast targeted cooling.

Mancooler specifications

- Watts – 0.55 – 1.1 kW

- Poles – 2 – 4 P

- Size – 300 – 400 mm

- Voltage – 240 – 415 V

- Air volume – 1,400 – 2,150 l/s

- Full load amps – 1.4 – 6.2 A

- Motor speed – 1,440 – 2,880 RPM

Mancooler features

- Adjustable discharge direction

- GRP adjustable pitch blades

- Heavy-duty wheels for ease of handling

- Inlet and outlet finger guards

- IP55 Motor

- Premium powder coated steel casing

- Top mount lifting hook

Mini Mancooler Specifications

- Watts – 0.55 – 5.5 kW

- Poles – 2 – 8 P

- Size – 400 – 1,000 mm

- Voltage – 240 – 415 V

- Air volume – 1,500 – 17,000 l/s

- Full load amps – 1.6 – 12.4 A

- Motor speed – 720 – 2,880 RPM

Mini Mancooler features

- Adjustable mount carry handles

- Extra heavy-duty construction

- GRP adjustable pitch blades

- Inlet and outlet finger guards

- IP55 Motor

- Premium powder coated steel casing

- Side mount carry handles

Air Circulators.

Fanquip’s Air Circulation Fans provide critical air movement and help to create a more comfortable and productive workspace. Circulating Fans are essential to many commercial working environments improving air quality, employee productivity and reducing perceived temperatures by evenly distributing cool air during summer and hot air during winter. Fan quip’s Air Circulators are available in various applications, including pedestal, ceiling and wall mount.

Pedestal Air Circulators

Pedestal mounted Air Circulators are among popular due to their portability, versatility and durability. Improving air circulation to create a more comfortable and safer working environment for employees. Facilities can make use of one efficient device in various locations within their workplace, saving time, energy, and, more importantly, money.

Pedestal Fan specs

- Watts – 0.37 kW

- Poles – 1 –3 P

- Size – 460 – 810 mm

- Voltage – 240 – 415 V

- Air volume – 3,000 – 17,000 l/s

- Full load amps – 1.03 – 2.4 A

- Motor speed – 900 – 14,000 RPM

Pedestal Fan features

- 2 speed motors (240V models only)

- Australian made

- Fixed head design – tilt & height adjustable

- GRP adjustable pitch blades

- Stainless steel or powder coated steel construction

- Washdown duty/hoseproof IP56 rating

Wall Mount Air Circulators

Wall Mount Air Circulators take up less floor space in comparison to pedestal fans, while providing the same cooling and airflow benefits. They are a cost-effective and energy-efficient solution for improving air quality and cooling in industrial environments. With their ease of installation, adjustable settings and wide area coverage, Wall Mount Air Circulators are an effective and practical option for many types of businesses.

Wall Fan specs

- Watts – 0.2 – 0.55 kW

- Size – 460 – 810 mm

- Voltage – 240 – 415 V

- Air volume – 3,000 – 17,000 l/s

- Full load amps – 1.03 – 2.4 A

- Motor speed – 900 – 14,000 RPM

Wall Fan features

- 2 speed motors (240V models only)

- Australian made

- Fixed head design – tilt & height adjustable

- GRP adjustable pitch blades

- Stainless steel or powder coated steel construction

- Washdown duty/hoseproof IP56 rating

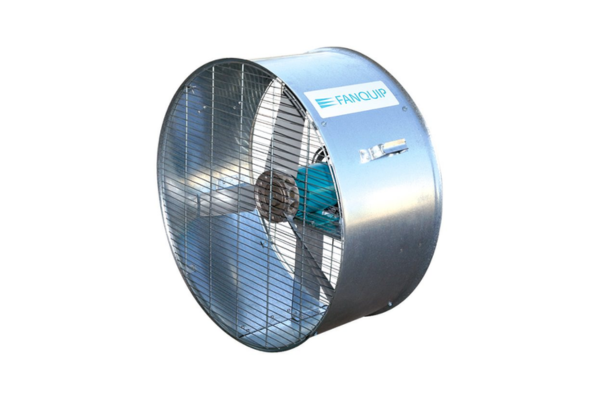

Utility Air Circulators

Fanquip’s Utility Air Circulators offers maximum air movement with high airflow with applications suitable for the agricultural industry. Providing poultry, dairy, and pig sheds with improved airflow and air quality, providing fresh environmental conditions with minimum power consumption and increased energy efficiency.

Utility Fan specs

- Watts – 0.15 – 0.37 kW

- Poles – 6 P

- Size – 800 mm

- Voltage – 240 – 415 V

- Air volume – 3,775 – 5,115 l/s

- Full load amps – 1.05 – 2.6 A

- Motor speed – 960 RPM

Utility Fan features

- Galvanised steel casing

- GRP adjustable pitch blades

- Inlet and outlet finger guards

- IP55 Motor

- Lead and 3 pin (plug supplied on 240V model only)

- Lightweight for fast and easy installation

- Side mount hanging blades

Giant Fans.

Installing a Giant Fan can effectively circulate the air throughout the entire space and create an even draft. Industrial Giant Fans are designed with powerful motors that spin blades at a slower speed to ensure maximum airflow throughout large areas making them ideal for warehouses and similar settings.

Fanquip’s Giant Fans provide a large volume of air for widespread coverage throughout your facility. A high volume low-speed (HVLS) Giant Fan can do so much more than just help you maintain comfortable indoor temperatures. Our multi-purpose Giant Fans can be used in the summer as a cooling solution or during winter for heat destratification and providing energy savings year-round.

Specs

- Watts – 1.5 kW

- Size – 3,700 – 7,300 mm

- Voltage – 415 V

- Air volume – 5,800 – 13,200 l/s

- Full load amps – 1.89 – 3.23 A

Features

- Can be used for summer cooling or winter heat re-stratification

- High air volume for large area coverage

- Wall mount control box with variable speed control

- Whisper quiet – extremely low noise levels

Transformer Cooling Fans

Transformer Cooling Fans are an efficient and reliable cooling solution that is critical for the safe and efficient operation of transformers in industrial and commercial settings. With their energy efficiency, versatility, minimal maintenance, and safety benefits, transformer cooling fans are an essential investment for any electrical system. Oil-cooled transformers require fans to help remove heat from inside the transformer by creating more airflow over its cooling fins. Fanquip’s Transformer Cooling Fans regulate the temperature, preventing overheating and extending your equipment’s life.

Transformer Fan specs

- Watts – 0.37 – 0.75 kW

- Poles – 4 – 6 P

- Size – 600 mm

- Voltage – 415 V

- Air volume – 2,300 – 3,700 l/s

- Full load amps – 1.32 – 1.94 A

- Motor speed – 960 – 1,440 RPM

Transformer Fan features

- Australian made to suit Australian conditions

- Continuously rated

- GRP adjustable pitch blades

- Hot dip galvanised casing

- IP56 motor

Industrial ventilation solutions.

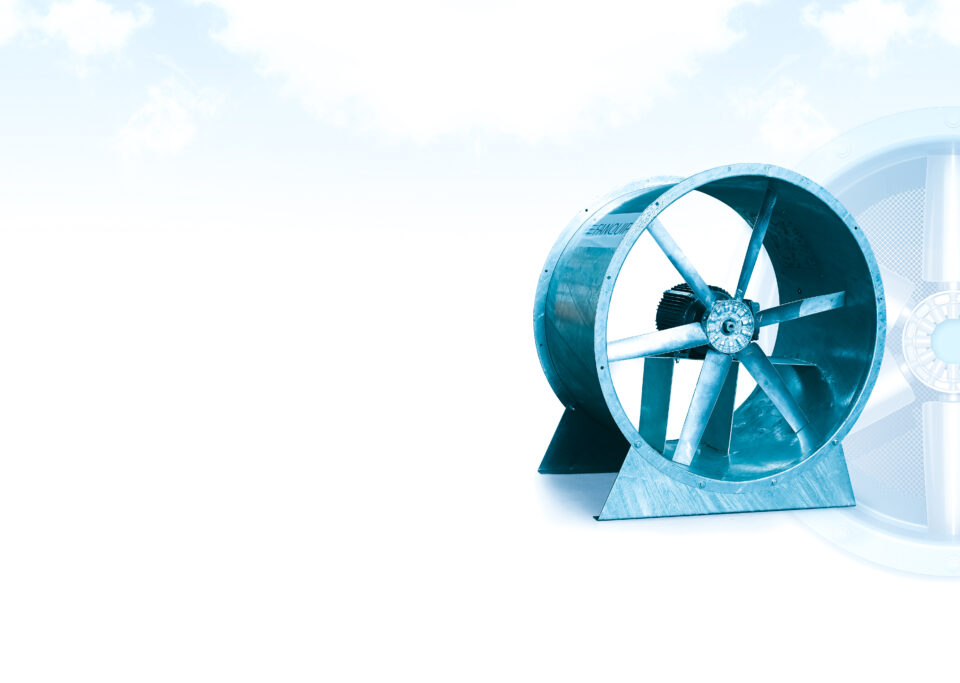

Axial Fans.

Axial fans are well-suited for applications that require a large volume of air to be moved over a long distance. This type of fan uses blades to push air directly ahead, making it very efficient at moving air in a straight line. Axial Fans are ideal for industrial settings and often ventilate large spaces such as factories, manufacturing facilities, warehouses, or underground mining operations.

Belt Drive Axial Fans

Belt Drive Axial Fans move enormous quantities of air at low pressures, making them ideal for various applications. The motor is installed independently of the fan blades and connected via the belt and pulley system. As the motor is externally located and kept away from the airstream, Belt-Driven Axial Fans are safer to use in settings where the air temperature or fumes present pose a safety hazard. With their low noise operation, customisable air flow rates, and energy-efficient belt drive system, they are an ideal solution to reduce energy costs, improve worker safety and comfort, and maintain a clean and healthy working environment.

Belt Drive Axial Fan specs

- Watts – 0.55 – 5.5 kW

- Poles – 2 – 16 P

- Size – 300 – 1,500 mm

- Voltage – 240 – 415 V

- Air volume – 654 – 25,500 l/s

- Full load amps – 1.63 – 8.2 A

- Motor speed – 720 – 2,880 RPM

Belt Drive Axial Fan features

- Aerodynamic belt tube

- External grease points

- GRP adjustable pitch blades

- Heavy industrial rolled casing

- Hot dip galvanised casing

- IP55 Motor

- Australian made

Direct Drive Axial Fans

Direct Drive Axial Fans offer many advantages, including energy efficiency, due to reduced friction and minimal maintenance. This fan type can handle hazardous fumes, removing and dispensing contaminated air from industrial processes which generate heat, steam, dust or other noxious emissions. Direct Drive Axial Fans offer a cost-effective solution for businesses looking to improve air flow and ventilation in their facilities.

Direct Drive Axial Fan specs

- Watts – 0.37 – 22 kW

- Poles – 2 – 6 P

- Size – 300 – 2,200 mm

- Voltage – 240 – 415 V

- Air volume – 654 – 55,440 l/s

- Full load amps – 1.03 – 12.4 A

- Motor speed – 720 – 2,880 RPM

Direct Drive Axial Fan features

- GRP adjustable pitch blades

- Heavy industrial rolled casing

- Hot dip galvanised casing

- IP55 Motor

- Australian made

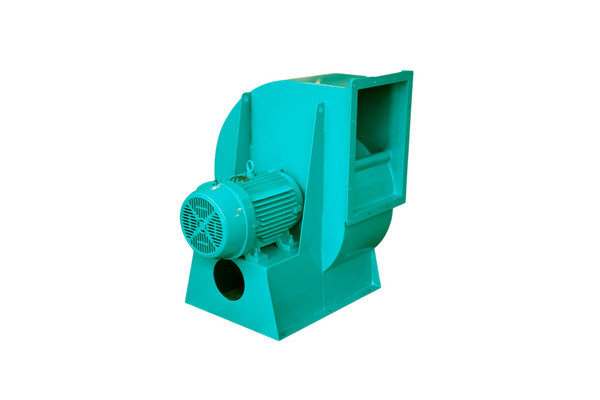

Centrifugal Fans.

Centrifugal fans use centrifugal force to draw air into the blades and then move it out at a 90-degree angle, creating a rotating column of air. These fans are very efficient at conveying gas or other materials, which is why they are often used in air conveyor systems or other materials handling processes. Centrifugal fans can also be used for filter flushing, gas boosting, and aeration. With a diverse range of applications, Centrifugal fans can also be used as a part of cooling and drying systems.

Backwards Inclined Centrifugal Fans

Backwards Inclined Centrifugal Fans are the perfect solution for clean or light dust air processes, especially in ducted systems. With low noise and robust construction our locally made fans are well suited to any commercial or industrial application.

Backwards Inclined Centrifugal Fan options

- Watts – 1.1 – 7.5 kW

- Size – 300 – 600 mm

- Static pressure – 284 – 4 Pa

- Air volume – 236 – 5,500 L/s

Backwards Inclined Centrifugal Fan features

- Available in painted. HDG. stainless steel

- Clean air handling fan

- High volume – Low noise

- IP55 Motor

- Australian made

- Custom arrangements/specifications

- Galvanised/stainless steel

- Hazardous locations (flameproof)

- Intrinsically safe motors

Roof & Exhaust Fans.

Exhaust & Roof Fans reduce heat load by extracting hot air, helping to maintain lower indoor temperatures. Cooling solutions such as industrial Giant Fans, Air Circulators, or HVAC systems can be used in conjunction with exhaust or roof fans to improve their overall effectiveness. Exhaust and Roof Fans help to expel stifling air as it rises, allowing cool air to circulate and reducing humidity levels.

Vertical Discharge Roof Fans

Designed for vertical discharge applications, roof fans can help control humidity within a space by removing heat, dust, steam, smoke, or noxious gasses as it rises to the ceiling. Proudly Australian-made, Fanquip’s Vertical Discharge Roof Fans are hot-dipped with galvanised steel construction and weather-proof butterfly dampers that can withstand all environmental conditions when mounted on a building’s roof.

Vertical Discharge Fan options

- Watts – 0.37 – 3 kW

- Poles – 4 – 8 P

- Size – 300 – 1,500 mm

- Voltage – 240 – 415 V

- Air volume – 1,900l/s to 19,000l/s

- Full load amps – 1.03 – 7.8 A

- Motor speed – 720 – 2,880 RPM

Vertical Discharge fan features

- Australian made

- Butterfly damper to prevent rain ingress

- GRP adjustable pitch blades

- Hot dip galvanised casing

- IP55 Motor

- Vertical discharge of airflow

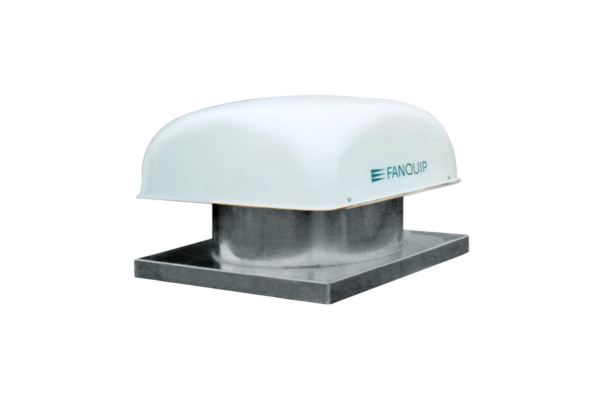

Profile Base Hooded Roof Fans

Profile Based Hooded Roof Fans are an effective way to improve air quality, as they help to remove humidity, heat, and harmful pollutants from the air. Profile Base Roof Fans can cut installation time and costs by as much as 60%, as no flashings are required. Follow the simple installation process from Fanquip’s installation guide; the fibreglass profile base is overlapped and underlapped from all sides, ensuring a seamless weatherproof finish, and removing the feed for upstands and flashings.

Profile Base Roof Fan options

- Watts – 0.37 – 2.2 kW

- Poles – 4 – 8 P

- Size – 300 – 1,200 mm

- Voltage – 240 – 415 V

- Air volume – 1,480l/s – 14,000l/s

- Full load amps – 4.2 A

- Motor speed – 720 RPM

Profile Base Roof Fan features

- Birdmesh protection fitted

- Exhaust or Supply Air versions available

- Fiberglass hood and base / Hot dip galvanised casing

- GRP adjustable pitch blades

- IP55 Motor

- Profile base to match a wide range of roof profiles

- Simple installation – no upstand or overflashings required

- Weatherproof design

Curb Base Hooded Roof Fans

Fanquip’s Curb Base Hooded Roof Fans discharge air out through the roof with a heavy-duty hood in place to stop rain ingress. Place strategically from the major openings of a warehouse, workshop, storage depot, processing plant or other large complex to create airflow over a large area before it is extracted. Made from fibreglass or hot dip galvanised steel, Fanquip’s Hooded Roof Fans are heavy-duty and lightweight and can withstand the force of extreme weather conditions including erosion.

Curb Base Roof Fan options

- Watts – 0.37 – 2.2 kW

- Poles – 2 – 8 P

- Size – 300 – 1,200 mm

- Voltage – 240 – 415 V

- Air volume – 1,400l/s to 14,000l/s

- Full load amps – 1.3 – 6.6 A

- Motor speed – 720 – 2,880 RPM

Curb Base Roof Fan features

- Birdmesh protection fitted

- Exhaust or Supply Air versions available

- Fiberglass hood and base / Hot dip galvanised casing

- GRP adjustable pitch blades

- IP55 Motor

- Weatherproof design

Wall Plate Exhaust Fans

Fanquip’ s Wall Plate Exhaust Fans are well suited for environments requiring the removal of heat, steam, and dust. They are highly versatile with numerous applications including an exhaust or air supply fan.

Wall Plate Exhaust Fan options

- Watts – 0.37 – 3 kW

- Poles – 2 – 8 P

- Size – 300 – 1,500 mm

- Voltage – 240 – 415 V

- Air volume – 654 – 22,000 L/s

- Full load amps – 1.3 – 7.8 A

- Motor speed – 720 – 1,440 RPM

Wall Plate Exhaust Fan features

- GRP adjustable pitch blades

- Premium powder coated steel casing

- Inlet finger guard

- IP55 Motor

End Wall Exhaust Fans

Fanquip’s End Wall Exhaust Fans are low noise and belt driven, designed for ventilating large buildings or warehouses. Fanquip’s End Wall Exhaust Fans include a gravity closing louvre for external weather protection.

End Wall Exhaust Fan options

- Watts – 0.55 – 1.1 kW

- Poles – 4 P

- Size – 917 – 1,270 mm

- Voltage – 415 V

- Air volume – 5,140 – 11,055 L/s

- Full load amps – 2 – 2.8 A

- Motor speed – 1,440 RPM

End Wall Exhaust Fan features

- Galvanised casing

- Galvanised gravity closing damper

- Inlet finger guard

- IP55 Motor

- Stainless steel fixed blades

Side Wall Exhaust Fans

Featuring a heavy duty weatherproof design and galvanised construction, Fanquip’s Side Wall Exhaust Fans are used for extracting large volumes of heat, steam, or dust from industrial or agricultural buildings.

Side Wall Exhaust Fan options

- Watts – 0.37 – 1.5 kW

- Size – 300 – 1,000 mm

- Voltage – 240 – 415 V

- Air volume – 600 – 10,800 L/s

- Full load amps – 1.03 – 6.6 A

- Motor speed – 720 – 1,440 RPM

Side Wall Exhaust Fan features

- Heavy duty waterproof design

- Aluminium gravity closing damper,

- GRP adjustable pitch blades

- Hot dip galvanised casing / galvanised housing

- Inlet finger guard

- IP55 Motor

At Fanquip, we have provided high-quality industrial fans and ventilation solutions for various industries since 1984; Our reliable industrial cooling and ventilation products help customers keep their workspaces cool and maintain high air quality. Whether you need an extensive ventilation system or cooling fans capable of circulating airflow through large scale facilities, Fanquip has something to suit your requirements. Contact us to learn more.

Resources

- University of Sydney – https://www.sydney.edu.au/news-opinion/news/2019/03/14/why-the-perfect-office-temperature-is-a-myth.html