According to the Medical Journal of Australia, hazardous occupational exposures lead to 15% of adult-onset asthma, 15% of chronic obstructive pulmonary disease, and 10-30% of lung cancer cases.

Dust is considered an occupational hazard, as it contributes to lung conditions. What are industries doing to mitigate this risk?

Keep reading as we discuss the consequences of dust exposure in the workplace and the dust extractor equipment that can help you to extract pollutants from the air on your job site.

Health issues caused by dust

Dust can cause both short-term and long-term health issues for workers. Here is a list of the various health issues that occur when preventative measures are not taken to mitigate dust and pollutants:

- Respiratory problems (difficulty breathing, coughing).

- Chronic obstructive pulmonary disease.

- Lung cancer.

- Adult-onset asthma.

- Lead poisoning.

- Allergic reactions.

- Silicosis.

Pneumoconiosis, or ‘dusty lung’, is a general term for respiratory conditions caused by dust. With the wealth of issues this occupational hazard can cause, there needs to be an increased focus on industrial ventilation and extraction.

How do industrial dust collectors improve safety?

Industrial dust collectors provide the solution to occupational lung hazards, performing the following functions for your manufacturing warehouse, construction site, or industrial facility:

- Particulate capture – industrial dust collectors use cyclonic action, electrostatic precipitation, or filtration to separate and remove dust particles from the air. They can help to reduce the dust in the air caused by material handling, cutting, or grinding.

- Improving air quality – an industrial dust collector removes fumes and dust from the air while promoting airflow. This ensures that dust does not damage essential equipment on site while reducing fire risk and providing more clean and breathable air.

- Ensuring compliance – an industrial dust collector helps companies maintain industry compliance to provide occupational safety and reduce pollutant emissions for environmental responsibility.

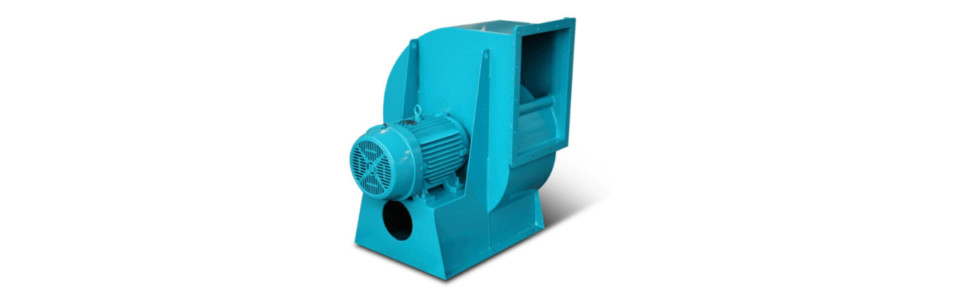

What’s the difference between an industrial dust collector and centrifugal fans?

When deciding on a solution to improve air quality, it’s essential to understand the difference between industrial dust collectors and centrifugal fans. Here are some of the key differences to help you know which solution you require:

- An industrial dust collector removes dust particles from the air, whereas a centrifugal fan provides cooling, airflow, and ventilation functions to improve air quality.

- An industrial or drill dust collector has inlet ducting, filter media, and filter cleaning components. A centrifugal fan, on the other hand, consists of a propellor or fan wheel to improve airflow.

Industrial dust collectors, drill dust collectors, and cyclone dust collectors perform filtration for the air, while centrifugal fans do not.

While both solutions will mitigate the dust particles in the air, the centrifugal fan is not as efficient in removing and capturing these dust particles. It simply provides a flow of clean air while performing extraction functions.

To reduce the pollutants emitted from your industrial operations to the surrounding environment, you should prioritise a dust collector. A centrifugal fan will not prevent dust and contaminants from entering surrounding ecosystems and habitats, which could cause lasting damage.

How many 1HP industrial dust collectors do I need?

To determine how many 1HP industrial dust collectors you require, you must consider several factors:

- Air volume and capture points – you must locate equipment and tools on your site, such as cutting and grinding equipment, that emit high amounts of dust. These are capture points that should be fitted with industrial dust collectors. Additionally, you should calculate the air volume.

- Distance – it is essential to analyse the ductwork on your facility and determine the distance between each capture point.

- Dust collector efficiency – to determine the optimal distance for your dust collector system, you should also analyse the dust collector’s efficiency regarding filtration efficiency and dust capturing capacity.

By considering these factors, you can develop a strategy for industrial dust collector placement to eliminate dust from the air – particularly in areas where cutting and grinding occur.

Calculating the number of dust collectors you need can be outsourced to a ventilation professional. They can analyse your facility’s needs and develop a strategy.

Fanquip provides industrial dust collectors for industry compliance and occupational safety

Industrial dust collectors are an essential investment. You must comply with industry regulations and take steps to prevent litigation due to occupational lung conditions. Centrifugal fans are insufficient to capture and eliminate dust from the air, and industrial dust collectors must also be used.

Fanquip has a team of ventilation experts on hand to discuss the scope of your needs and plan your industrial dust collector placement. Contact us today for a consultation.