The pandemic has illuminated the importance of maintaining clean and sanitary workspaces, particularly in industries with inherent risks. Industries such as mining and metals, manufacturing, smelters, refineries and welding require stringent safety measures to protect employees from the cloud of dust and fumes they inevitably produce.

It’s crucial that businesses take the necessary precautions to keep employees safe at work, although it can be challenging to follow these precautions without adequate processes, procedures and equipment in place. Risks posed by inadequate dust and fume management systems are overwhelming. Airborne hazards have the potential to cause or exacerbate respiratory diseases such as asthma, asbestosis, respiratory cancer and chronic obstructive pulmonary disease [1]. Therefore a well-thought-out approach is essential for any responsible employer wanting to provide a safe workspace for their staff.

Understanding fume and dust hazards and the associated control measures enables you to create a safer, healthier work environment for your workers and customers.

The dangers of dust and fumes

Airborne dust and hazardous chemicals are a significant health concern for many Australian workers. According to recent studies, almost one in four experienced both airborne hazards as well as dermal contact with compounds and chemicals [2]. This alarming statistic acknowledges how crucial health and safety protocols are in protecting our workforce from potential harm.

Airborne dust and fumes are a reality for some industrial workplaces. Employees within industries such as manufacturing, vehicle repair shops, bakeries, warehouses, or workshops are particularly vulnerable to their potentially harmful effects. In addition to causing discomfort and creating hygiene problems, constant exposure to these particles and substances can lead to debilitating illnesses and medical conditions like asthma, chronic obstructive pulmonary disease, asbestosis, and cancers of the respiratory system such as mesothelioma and lung cancer [1].

Dust accumulation can become explosive in certain manufacturing instances where combustible raw materials are being used. Fortunately, this is a rare instance for both Australia and New Zealand, with only a handful of deaths reported as a result of combustible dust incidents [3]. Therefore, employers must take steps to ensure the safety of their workers by regulating air quality standards and providing them with adequate protection against dust inhalation.

In the past, many metalworking facilities, welding shops, and similar industries relied on exhausting air outdoors to control the dangerous dust and fumes, but it is rarely sufficient on its own. Not only does it not guarantee a healthy working environment, but indiscriminately exhausting amounts to environmental pollution – which can result in hefty fines and legal repercussions depending on your location.

A far more practical solution is investing in effective ventilation solutions that protect workers from hazardous airborne dust while minimising the impact on outside environments. This can be done through an appropriate selection of extraction systems, filtration systems, and other air-handling products designed according to each specific application.

Why is dust extraction important?

Dust control systems are essential for the health and safety of employees with additional benefits associated with fume extraction and dust control systems.

Effectively manage silica dust in the workplace

Silica dust is a major health concern for those working with brick, tile, stone, concrete, gravel, clay and plastic. Fine dust is released when working with these materials, known as respirable crystalline silica or silica dust. Silica dust is 100 times smaller than a grain of sand and can be inhaled into your lungs, causing cancer such as silicosis, kidney disease, lung cancer and obstructive pulmonary disease [4].

It’s essential that employers adopt adequate safety controls to effectively manage health and safety of their workers and others at work. The Queensland Government’s Code of Practice for managing respirable crystalline silica dust exposure in construction and manufacturing has been developed to ensure silica dust is managed safely and workers are protected [5]. The elimination of silica dust is the most effective prevention measure. Utilise Fanquip’s fume and dust extraction systems for the filtration and extraction of powders and dust.

Improve work quality

Dust extraction management is key to ensuring the quality of any project as dust particles can easily mix with chemicals, liquids, and mixed substances. Dust control systems are an effective way to keep the finished product looking its best and ensure that all chemicals and materials used in a job are of the highest-quality.

Improve productivity

Dust and small debris can easily clog up machines and equipment, affecting performance. An adequate dust control system and maintenance schedule will help reduce clogs and keep machines running efficiently so you don’t experience unnecessary downtime or production delays.

Cost savings

Regular maintenance requirements are a fact of life when dealing with industrial machinery. However, by installing a proper dust extraction system, you can significantly reduce these maintenance requirements as well as their associated costs. Dust particles can cause friction with machine components, leading to damage over time. Excessive heat can also occur due to friction, leading to further damage. Installing a dust extraction system that filters out most particulate matter helps reduce this wear and tear significantly, saving you money on repairs and replacements down the line.

All these benefits make investing in proper dust extraction management systems an excellent choice for Australian industries. Investing in these systems offers peace of mind that safety standards are being met and exceeded while also improving efficiency.

Safety measures to control fumes and dust

Whether you are in the manufacturing, mining, welding, or automotive service industry, it is important to have a reliable fume and dust extraction system in place to manage these particles effectively. There are a wide variety of products available for extractive dust and fumes management systems, with suitable solutions for any environment or application.

Portable Fume Extractors

Portable Fume Extractors are a reliable solution for industries that require flexibility. These devices can be moved around easily and quickly set up in different parts of the workspace. They come with adjustable arms and suction nozzles, allowing users to quickly adjust the position of the device according to their needs. Portable Fume Extractors are ideal for small-scale operations because they offer an easy-to-use solution that can be adjusted as needed.

Fanquip’s Fume Extractors are designed to maximise dust removal with the use of an air mover, engineered using the Venturi principle to increase pressure differential, in turn improving extraction efficiency. This makes our extractors ideal for service and repair workshops, manufacturing centres, laboratories, and other areas where hazardous substances can compromise health.

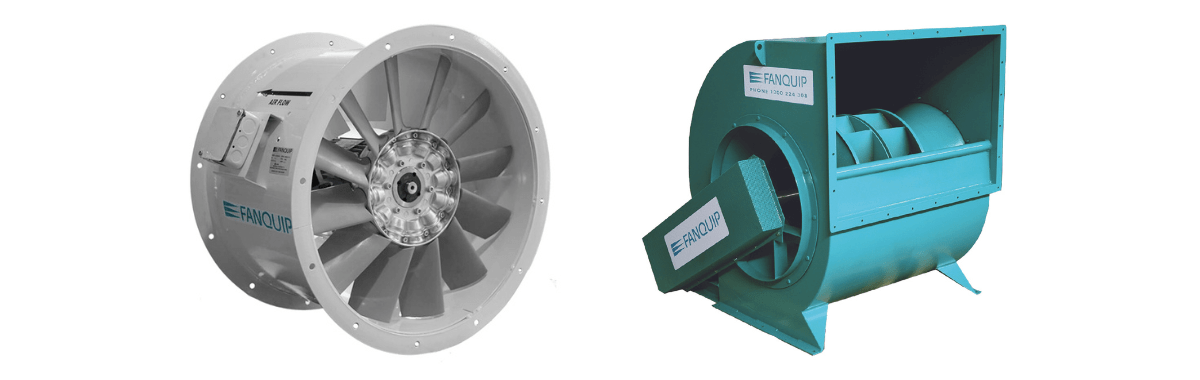

Axial Fans & Centrifugal Fans

Axial Fans and Centrifugal Fans are both popular among industrial applications as they provide a powerful airflow while remaining relatively compact in size. Axial Fans move air along their axis while Centrifugal Fans move air outwards in a circular pattern; this makes them ideal for large-scale operations where multiple machines need to be handled at once.

Fanquip’s Axial Fans are the economical and reliable choice for efficient air movement in a wide range of industrial applications. They require minimal maintenance and have the power to move large volumes of air over long distances – perfect for warehouses, mining operations or any workplace dealing with dust and fumes. In addition to their robust Axial models, Fanquip provides a range of high-pressure Centrifugal Fans that are well suited to medium- to heavy-duty material handling applications, as well as custom solutions based on detailed customer requirements.

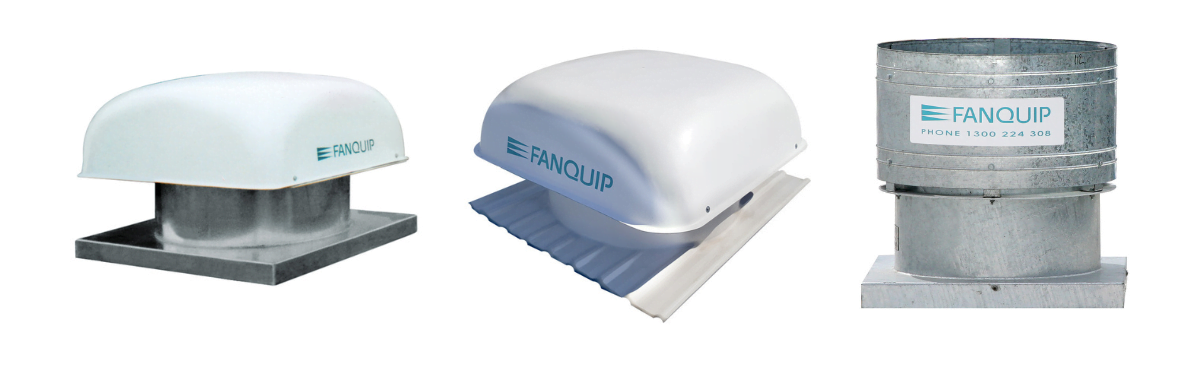

Roof Fans

Roof Fans are another type of fan that is designed specifically for larger spaces such as warehouses or factories; they are usually installed on top of the roof where they can draw out hot air effectively while providing maximum airflow coverage throughout the entire space.

Fanquip is a comprehensive engineering solutions provider offering weatherproof, easy-to-install Roof Exhaust and Supply Fans to remove heat, dust, fumes, steam, and other airborne particles in commercial and industrial applications. Each fan option utilises the latest technology to effectively deliver superior air extraction results while at the same time reducing energy costs.

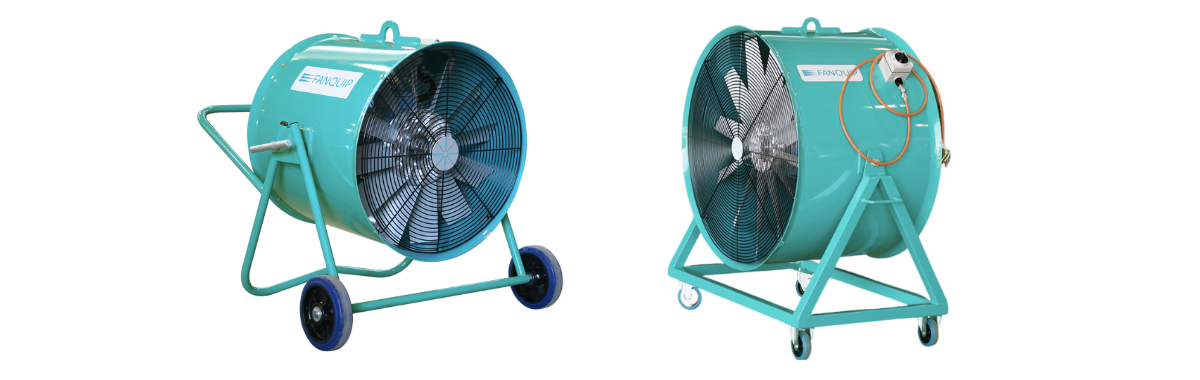

Mancoolers

Mancoolers are used to effectively manage dust and fumes in tunnels, construction sites, mine sites and industrial sites. Our heavy-duty flexible ducting can be used in conjunction with Mancoolers for mobile fume and dust extraction. Australian-made with a heavy-duty frame and large-diameter wheels, Fanquip’s Mancoolers are designed for rugged conditions and are suitable for a wide range of applications. Utilise this as an air supply or exhaust system to effectively extract hazardous particles.

Portable Blower Extractors

Portable Blower Extractors are used extensively in industrial applications as an air supply or extraction source. These systems are great for confined spaces for extracting dust and fumes, such as welding fumes and paint fumes. With a wide range of applications including mine sites, tunnel projects, shipbuilding, sugar mills, flour mills and power stations. Fanquip’s Portable Blower Extractors are lightweight, portable and effective for ventilating and extracting fumes from confined spaces.

Fanquip’s ventilation systems

Fanquip is Australia’s leading industrial solutions provider with expert guidance, products and services for industrial dust and fume control. Dust and fumes pose serious health risks to workers in manufacturing industries. Fanquip’s expertise in designing customised fans and fan systems will help ensure a safe working environment free of hazardous dust particles.

With Fanquip’s impressive range of reliable systems, you can rest assured that every aspect of your industrial operations will be managed efficiently and safely. Ensure the safety of your employees by effectively and efficiently managing industrial dust and fumes. If you would like a custom solution or extraction system for your industrial workplace, please contact us online or call 1300 224 308.

Resources

- Safe Work Australia – https://www.safeworkaustralia.gov.au/system/files/documents/1702/nhews_exposure_dust_gases_vapours_smoke_fumes_provision_contols_airborne_hazards_australian_workplac.pdf

- Safe Work Australia – https://www.safeworkaustralia.gov.au/system/files/documents/1702/exposure-to-multiple-hazards-report.pdf

- Dust Safety Science – https://newson-gale.com/wp-content/uploads/2021/05/Dust-Safety-Science-2020-YearEnd-Incident-Report-5-5.pdf