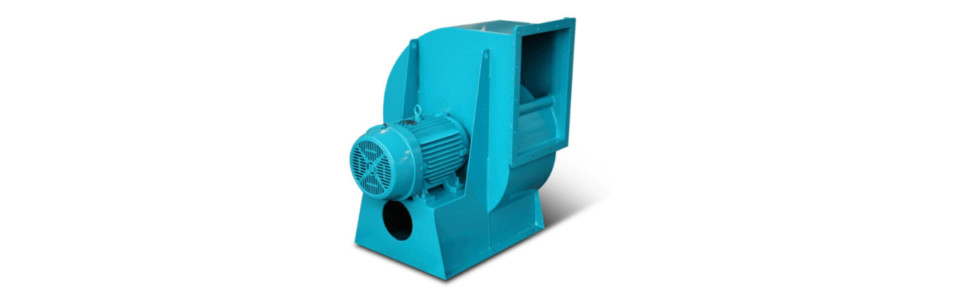

Material-handling fans and blowers play an essential role in ventilation. They are applicable in hazardous locations, which makes them the ideal solution for mining, heavy manufacturing, smelting, and refinery industries.

What is a centrifugal blower fan used for?

Let’s explore the main applications of centrifugal blower fans.

- Underground ventilation – in the mining industry, the drilling process can cause heavy amounts of dirt, debris, and combustible contaminants in the air. When these contaminants accrue, there is a risk to workers’ lung health. There is also the risk of combustion, leading to fatalities. A centrifugal fan shifts gases, dust, and fumes from tunnels and shafts to ensure on-site safety.

- Heavy manufacturing – during heavy manufacturing processes, there is a need for heavy-duty manufacturing equipment. Centrifugal fans provide the ventilation to cool down equipment, preventing failure or breakage.

- Smelting – centrifugal fans support gas scrubbing in smelting environments. Smelting causes the emission of pollutants like sulphur dioxide. Gas scrubbers improve air quality to reduce risk to worker safety. Centrifugal fans provide sufficient airflow to ensure the efficiency of gas scrubbers.

- Refineries – refineries contain industrial burners which require combustion for operation. Centrifugal fans support controlled combustion by providing a steady flow of combustion air.

Centrifugal fan features

Now that you know the industrial applications of centrifugal fans, let’s discuss the features on offer. When evaluating centrifugal fans for your facility, you should keep these features in mind.

High airflow capacity

A high airflow capacity is necessary in industrial environments to maintain an industry-compliant airflow exchange rate. Centrifugal fans provide a high airflow capacity to move air and provide an input of fresh air, ensuring temperature control and air quality.

Pressure generation

Pressure generation is an important feature that helps to contain particles, fumes, and dust, preventing them from entering other areas in the facility and causing cross-contamination. Increased air pressure can also support air movement through ducts in an industrial setting. Centrifugal fans can generate the level of pressure required in an industrial setting.

Energy efficiency

Modern centrifugal fans are designed with energy efficiency in mind. The fan blades have aerodynamic optimisation, and the motor systems are enhanced to reduce energy consumption.

Noise control

One of the key concerns regarding ventilation solutions is the potential for noise hazards. With a centrifugal dan, there are insulated enclosures and materials for sound absorption that reduce the risk to workers.

Material durability

When exposed to corrosive materials, most fans will degrade over time. Centrifugal fans are designed with industrial settings in mind, providing corrosion resistance.

They are also equipped to handle high temperatures and high humidity levels to ensure you get the most out of your ventilation investments. You can even adopt a backward-inclined centrifugal fan to prevent contaminants from gathering on the fan blades.

Benefits of using a centrifugal fan

Here are some of the benefits of incorporating centrifugal force fans into your industrial ventilation strategy:

- Air exchange rate – a centrifugal fan can help you to maintain the required air exchange rate for your industry, set out in health and safety regulations.

- Maintaining temperatures – centrifugal fans ensure consistent temperatures by reducing air pockets, ensuring your equipment is safe, and ensuring workers do not overheat.

- Reducing contaminants – with a centrifugal fan, you can reduce the risk of workers inhaling dust and other contaminant particles, ensuring clean air and comfortable working conditions.

- Reducing the risk of liability – if you do not invest in a required ventilation system for your industry sector, you risk being held liable for illnesses and accidents occurring as a result.

What makes a centrifugal fan powerful?

A centrifugal fan, or material handling blower, is powerful due to its high airflow capacity. It can provide high-pressure differentials, allowing large airflow volumes to be delivered. This makes a centrifugal fan the most ideal solution for industries with higher ventilation requirements.

Do you require centrifugal fans? Choose Fanquip for your ventilation solutions

Centrifugal fans provide the high airflow capacity required in mining and heavy-duty manufacturing industries. They offer ventilation, air circulation, and contaminant management.

When planning your ventilation strategy, it is essential to understand your airflow exchange requirements and how many fans are needed to meet these requirements.

At Fanquip, we can support you with our extensive knowledge of industry ventilation requirements. Contact us today for assistance with your ventilation strategy.