In 2020, there were no fatalities in the offshore oil and gas industry in Australia out of 8.5 million total hours worked. The oil and gas industry faces many occupational hazards and has successfully managed these hazards to provide safer working conditions.

Did you know that ventilation is a crucial element in workplace safety for the oil and gas industry?

Keep reading as we explore why ventilation is instrumental to oil and gas operations and the top ventilation solutions to implement at your oil and gas facility.

Why do you need ventilation in the oil and gas industry?

Why is ventilation so crucial to oil and gas industry operations? Let’s take a look:

- Providing extraction – many hazardous vapours and gases, such as hydrogen sulphide and volatile organic compounds, are produced during oil and gas production processes. Drilling, refining, and storage facilities need ventilation to extract these harmful vapours and gases.

- Reducing the risk of combustion – many toxic and flammable gases present the risk of explosions and health hazards in an oil or gas facility. Ventilation provides better air quality while reducing the risk of combustion.

- Preventing respiratory issues – airborne particles such as silica dust and drilling mud can lead to serious respiratory complications for workers. A ventilation solution helps to remove these particles from the air to provide more safety for workers.

- Temperature and humidity regulation – industrial ventilation solutions provide temperature and humidity control in oil and gas facilities to prevent corrosion and ensure equipment does not degrade over time.

- Reducing environmental impact – ventilation solutions minimise the release of harmful toxins and pollutants into the atmosphere, helping companies comply with emissions regulations and provide more sustainable operations.

For these reasons, ventilation solutions are at the heart of on-site safety for oil and gas facilities.

Top ventilation solutions for the oil and gas industry

You must consider a ventilation strategy for your oil and gas facility to ensure your site is safe and protect workers’ health. To do this, you must consider which types of fans best suit your needs. Below are the top solutions to facilitate safety at an oil and gas facility.

Direct Drive Axial Fan

A Direct-Drive Axial Fan has a motor directly connected to the fan blades. There is no need for a belt or pulley, meaning the fan is more low-maintenance than a belt drive fan. This fan efficiently provides high airflow with low static pressure, decreasing the risk of ignition or combustion.

Transformer Cooling Fan

A Transformer Cooling Fan is the ideal solution to prevent your on-site transformer from overheating, which presents a fire risk and could degrade your equipment. They help to speed up the dissipation of heat for transformers. Transformer cooling fans are low-noise with built-in temperature and speed controls, allowing you to adapt your ventilation solution to the transformer’s cooling requirements.

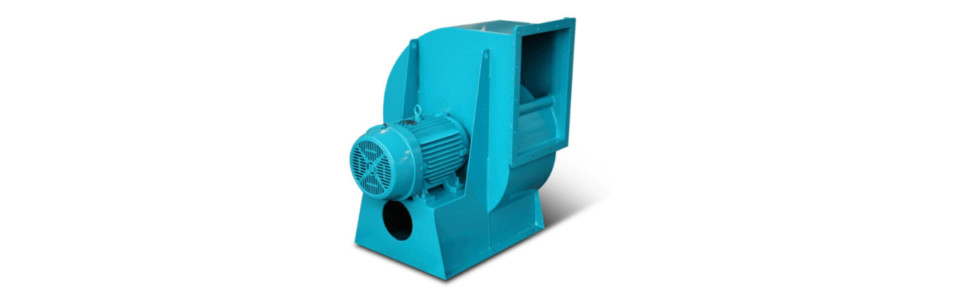

Centrifugal Fan

A Centrifugal Fan provides more pressure and a higher volume airflow than a Direct Drive Axial Fan. A Centrifugal Fan operates well in environments with high static pressure and can handle resistance to airflow effectively. They are ideal for industrial ventilation, pollution control, and temperature regulation.

Venturi Air Mover

A Venturi Air Mover creates different air pressures to move air efficiently. With an air mover, you can transport air over long distances and against resistance, which is why this is a popular solution in the mining sector. You should choose a Venturi Air Mover for reliable and effective long-distance air movement.

Oil and gas industry ventilation challenges

What challenges might you face when implementing a ventilation strategy for your oil and gas facility?

- Hazardous gases and vapours – you must ensure proper ventilation and airflow to control the number of hazardous gases and vapours in the air, creating a safe working environment.

- Due to limited access and complex geometry, confined spaces – tanks, pipelines, and offshore platforms can be challenging to ventilate. The potential for toxic and flammable gases to accumulate in these areas is high, so specialised planning is required.

- Harsh environments – the extreme temperatures, raised humidity levels, corrosive substances, and combustible materials at oil and gas facilities can make ventilation planning difficult, as the equipment must be able to withstand these conditions.

Speaking to a ventilation expert will help you to develop your ventilation strategy with these challenges in mind.

Choose Fanquip for oil and gas industry ventilation solutions

Ventilation is instrumental in keeping oil and gas facilities safe while mitigating their effect on the surrounding environment and ecosystems. However, there are special considerations to consider when planning your ventilation strategy.

If you contact us at Fanquip, you can access expert advice to devise the best strategy for ventilating your oil and gas facility. Our team has the experience and knowledge to help you ensure complete ventilation and control for hazardous airborne materials.