Textile and clothing manufacturing is a small yet vital sector, contributing 1.5% to the Australian GDP. With the decline of fast fashion and the surge in demand for high-quality, ethically made local clothing and fibre products, Australian-made textiles are experiencing a renaissance. However, these manufacturing processes wouldn’t be safe or efficient without proper ventilation systems to ensure optimal air conditions.

Keep reading as we explore why ventilation is essential for the textile industry and discover the top ventilation solutions to keep your operations running smoothly.

Why is ventilation essential for the textile industry?

Different Australian fibre products and materials are used in the textile industry to create clothing and valuable manufacturing materials. Here are some of the complex fabric manufacturing processes involved in textile operations:

- Production of fibres

- Arrangement of fibres into yarns

- Generating fabric from raw materials

- Processing fabrics to perfect the finished product

For each process, manufacturers must maintain optimal humidity, temperature, and air conditions to ensure quality and workability aren’t compromised. Textile facilities require industrial-grade ventilation solutions to maintain ambient conditions. The reliability and performance of these ventilation systems are paramount; failure could lead to material spoilage, increased industry waste, and financial losses.

Additionally, poor ventilation can cause the buildup of harmful gases such as carbon dioxide, which can negatively affect worker performance and safety. Ensuring a continuous supply of fresh outdoor air and reducing indoor pollutants is critical to maintaining a healthy work environment.

How does ventilation benefit textile operations?

What will you gain by ensuring proper ventilation for your textile industry operations? Let’s take a look:

Worker health

Ventilation systems help manage airborne contaminants like dust, lint, bacteria, and viruses, ensuring clean, breathable air quality. Poor air quality can lead to respiratory issues such as aggravated asthma, chronic bronchitis, or other severe health problems. Effective ventilation, combined with proper face masks and personal protective equipment, lowers the risk of respiratory conditions, safeguarding worker health. In extreme cases, exposure to poor air quality might necessitate medical interventions like invasive ventilation, where a breathing tube is used to assist with breathing, which is why filtration and ventilation are so important.

Managing air pollution

In an industrial environment, pollutants from manufacturing processes and external sources can seep into the air. Standard air conditioning units can’t effectively manage these pollutants. Without proper filtration, fabrics risk contamination through electrostatic attraction or dust accumulation. Ventilation products, including exhaust fans and air filtration systems, help push air through filters to remove contaminants, stabilising working conditions. Proper ventilation systems are crucial in preventing the buildup of volatile organic compounds (VOCs) and other harmful chemicals released during textile processing.

Decreased waste

Industrial ventilation solutions regulate temperature and humidity levels while maintaining air quality. Consistent air conditions prevent dust buildup, mould growth, and fluctuations that can spoil materials. By ensuring stable environmental conditions, you reduce product spoilage, save valuable materials, and minimise waste, leading to cost savings. A well-ventilated environment also prolongs the life of machinery and equipment by preventing dust accumulation and overheating, reducing maintenance costs and downtime.

Seasonal adaptation

Ventilation depends on the season to provide optimal working conditions. In summer, proper ventilation keeps workers cool by providing air circulation and distributing temperatures evenly, preventing heat stress, dehydration, and other heat-related illnesses. Ventilation is also important during winter because it combats condensation, which can lead to mould and mildew growth, compromising both product quality and worker health. Natural ventilation methods, such as openable windows, combined with mechanical ventilation systems, improve indoor air quality year-round and reduce energy consumption by utilising passive airflow whenever possible.

Top ventilation solutions for the textile industry.

Now that you know the benefits of ventilation for textile operations, it’s time to equip your facility with the most effective solutions. Here are the top recommendations for textile industry ventilation:

Direct-Drive Axial Fan

Direct-Drive Axial Fans efficiently push large volumes of air, maintaining consistent humidity and temperature levels. They are more energy-efficient than belt-driven systems since they don’t require ductwork or belts, making them ideal for facilities needing continuous air circulation. Their compact design and low maintenance requirements make them suitable for a wide range of textile manufacturing environments.

Belt-Drive Axial Fan

While Belt-Drive Axial Fans may not be as energy-efficient, they offer more flexibility with fan speed control. This adaptability allows you to adjust airflow based on your facility’s size, air conditions, and seasonal changes. These fans are particularly useful in larger facilities where precise control over air conditions is necessary to maintain product quality.

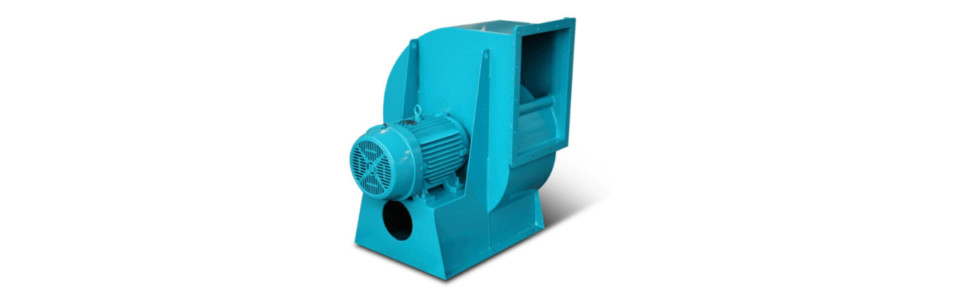

Centrifugal Fan

Centrifugal Fans are essential for facilities that need to manage high static pressure. These fans are ideal for dust extraction and air filtration, ensuring that contaminants are effectively removed from the work environment. By maintaining clean air, they help prevent textile contamination and reduce occupational lung hazards, often requiring intervention from healthcare professionals or respiratory therapists. Their robust design makes them suitable for heavy-duty applications where high performance and durability are required.

Choose Fanquip for textile industry ventilation planning

In the textile industry, ventilation is an integral component of product integrity and quality assurance. Fluctuations in temperature, humidity, and dust levels can lead to product spoilage, waste, and financial losses. Ventilation systems not only protect products but also ensure a healthier, safer environment for your workers.

Proper ventilation also contributes to energy efficiency and sustainability goals, helping your facility reduce its carbon footprint. By integrating natural ventilation with advanced mechanical systems, you can achieve optimal air conditions while minimising energy consumption.

If you’re planning the ventilation solution for your textile facility, our team of ventilation technicians and engineers can assist. We offer expert advice to help you comply with industry-specific ventilation regulations and recommend the best ventilation products for your needs. Contact us to learn more and optimise your facility’s air conditions today. Our comprehensive services include everything from system design to installation and maintenance, ensuring long-term performance and reliability.