In the demanding and hazardous environments of the oil and gas industry, reliable and robust ventilation solutions are non-negotiable. The critical nature of operations in this sector requires equipment that can withstand extreme conditions, ensuring safety, compliance, and optimal performance. Fanquip’s Australian-made industrial fans are engineered to meet these stringent requirements, providing dependable solutions for a range of applications within the industry.

Oil & Gas Ventilation Issues

The oil and gas industry faces unique challenges that significantly impact ventilation needs. The refining processes of oil, petroleum, and natural gases generate substantial heat, moisture, fumes, and noise, unlike any other industry. Additionally, the risk of explosive atmospheres due to the presence of flammable gases and vapours necessitates the use of explosion-proof equipment to ensure the safety of facilities and personnel. Addressing these issues effectively requires specialised ventilation solutions that can control hazardous airborne dust and fumes while withstanding the harsh operational environments.

Types of Industrial Fans in the Oil & Gas Industry

Fanquip offers a variety of industrial fans designed to meet the diverse needs of the oil and gas sector:

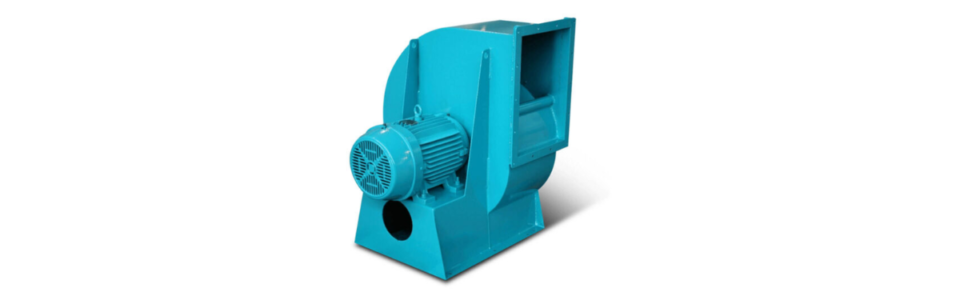

Centrifugal Fans

Our Backward Inclined Centrifugal Fans are ideal for clean air handling applications, offering high volume air movement with low noise levels. These fans feature IP55 motors and radial impellers, making them suitable for hazardous locations where safety is paramount.

Axial Fans

Direct Drive Axial Fans are another critical solution for the oil and gas industry, especially for applications requiring high airflow at a relatively low pressure. These fans are effective in ventilating large areas and can be installed on ceilings to direct air towards the floor, aiding in temperature regulation and gas dispersion.

Purging and Discharge Fans

Specifically designed to control and reduce the concentration of hazardous gases, purging and discharge industrial roof fans are essential for maintaining safe operating conditions, particularly in areas where gas flaring and venting are common practices.

Roof and Wall Exhaust Fans

To remove fumes, heat, and moisture from indoor spaces, roof and wall exhaust fans are employed. These units are crucial in preventing the accumulation of hazardous substances and in maintaining a safe and comfortable working environment.

Selecting the Right Fan for Oil & Gas Applications

Choosing the appropriate fan involves several considerations to ensure optimal performance and safety:

- Explosion-Proof Design: Given the potential for explosive atmospheres, fans used in the oil and gas industry must be designed to prevent ignition of flammable gases and vapours. Explosion-proof fans are a must in these environments.

- Material Construction: Fans, especially those exposed to corrosive gases or operating in marine environments, should be constructed from durable materials like stainless steel to withstand harsh conditions and prevent corrosion.

- Performance Requirements: Understanding the specific ventilation needs, including the volume of air to be moved (measured in litres per second), the static pressure requirements, and the fan’s operating point, is crucial in selecting the right fan.

- Energy Efficiency: Considering the power required to operate the fan is essential for managing operational costs. Fans with higher efficiency can significantly reduce energy consumption, contributing to cost savings and environmental sustainability.

The Cost-Effectiveness of Fanquip Solutions

Investing in high-quality industrial fans for the oil and gas industry is not just a matter of compliance and safety; it’s also a cost-effective decision. Fanquip’s fans are designed to provide maximum efficiency and reliability, reducing the need for frequent replacements and maintenance. By ensuring proper air movement and ventilation, these fans help maintain optimal operating conditions, which can lead to improved productivity and reduced operational costs.

Project: Beach Energy

Fanquip recently had the opportunity to collaborate with Beach Energy, a prominent player in the oil and gas sector, to address a critical ventilation challenge. Beach Energy was in urgent need of an effective solution to dilute and extract hazardous flammable gases from an oil gas pit measuring 5m x 7m x 2m deep. The project had specific requirements, including the need for the fan to operate on a 10 to 15 amp generator set and the inclusion of anti-static ductwork with a diameter of 300mm.

Understanding the urgency of the situation and its impact on Beach Energy’s operations, Fanquip swiftly provided a solution by deploying a Mini Mancooler, characterised by its compact size (300mm dia), efficiency (0.55kW, 2880rpm, 415V), and impressive air movement capacity (1,400l/s). The fan was built on a skid frame for easy mobility and durability, adhering to Fanquip’s commitment to Australian-made, extra heavy-duty standards. To complement the Mini Mancooler, Fanquip also supplied FRAS (Fire Resistant Anti-Static) Flexible Ducting, ensuring a safe and compliant solution to Beach Energy’s ventilation needs, allowing them to resume their critical work without further delay.

Conclusion

The oil and gas industry’s demanding and hazardous environments require specialised ventilation solutions that Fanquip is proud to offer. Our range of industrial fans, from centrifugal to axial, and explosion-proof models, are engineered to address the unique challenges of this sector. By selecting the right Fanquip fan for your oil and gas applications, you can enhance safety, ensure compliance, and achieve significant energy and cost savings, all while maintaining a high-performing workplace.