Axial flow fans are a fundamental component in various industrial and commercial settings, playing a crucial role in air management. Let’s explore the world of axial flow fans, a key element for businesses in Australia seeking efficient and robust air movement solutions.

Why Use an Axial Flow Fan?

Axial flow fans are preferred in many applications due to their ability to move large volumes of air efficiently. Their design allows air to flow parallel to the shaft, with blades mounted in a way that facilitates high volume air movement. These fans are energy efficient, have fewer moving parts, and can operate at higher speeds, making them ideal for environments where a steady flow of air is needed over long distances.

What are the Different Types of Axial Flow Fans?

There are several types of axial fans, each designed for specific applications.

Direct Drive Axial Flow Fans

Direct Drive Axial Flow Fans are an integral part of industrial and commercial ventilation systems, known for their efficiency and reliability. These fans have a motor directly connected to the fan blades, offering high efficiency and lower maintenance requirements.

Belt Drive Axial Flow Fans

A Belt Drive Axial Flow Fan is a type of axial fan where the motor is connected to the fan blades via a belt and pulley system. This configuration allows for flexibility in terms of fan speed and motor placement, making it suitable for environments where a lower fan speed is necessary or where the motor needs to be positioned away from the air stream due to harsh environments.

Short Cased Axial Flow Fans

Short Cased Axial Flow Fans are characterised by its short cylindrical casing, a design feature distinguishes it from other axial fans, which might have longer tubes or casings. The short casing allows for a more compact footprint, making these fans ideal for installations where space is limited.

Key Features of Axial Flow Fans

| Feature | Direct Drive Axial Fan | Belt Drive Axial Fan | Short Cased Axial Fan |

| Drive Mechanism | Direct motor-fan connection | Belt and pulley system | Varies (can be direct or belt drive) |

| Efficiency | High (less power loss) | Moderate | Depends on drive type and operating conditions |

| Maintenance | Low (fewer moving parts) | Higher (due to belts/pulleys) Requires periodic inspections | Depends on drive type |

| Noise Level | Generally lower | Potentially higher | Depends on drive type |

| Speed Control | Fixed (not easily adjustable) | Adjustable (via pulley sizes) | Variable speed control |

| Motor Placement | Close to the fan (in the airstream) | Away from the fan (flexible placement) | Close to the fan (typically) |

| Compact Design | More compact | Less compact | Very compact |

| Suitability for Harsh Environments | Less suitable (motor exposed to airstream) | More suitable (motor can be isolated) | Varies (depends on construction and materials) |

Where are Axial Flow Fans Used?

Axial flow fans are chosen for their efficiency in moving air over long distances and their adaptability to various environments, making them a popular choice across a wide range of industries.

- Industrial Ventilation: In manufacturing plants, warehouses, and workshops, axial fans are used to ventilate large spaces, removing stale air, smoke, or fumes and ensuring a healthy working environment.

- HVAC Systems: Axial flow fans are a key component in heating, ventilation, and air conditioning (HVAC) systems, particularly in large commercial buildings, where they help circulate and regulate air flow.

- Cooling Systems: They are widely used for cooling purposes, such as in cooling towers, heat exchangers, and air-cooled condensers, where they help dissipate heat efficiently.

- Agriculture: In agricultural settings, axial fans are used for ventilating greenhouses, barns, and livestock housing to maintain optimal environmental conditions.

- Mining Operations: In mining, axial flow fans are essential for providing ventilation, removing contaminated air, and ensuring the safety of the miners.

- Exhaust Systems: They are frequently used as exhaust fans in kitchens, bathrooms, and industrial settings to expel odorous or contaminated air.

- Automotive and Aerospace Industries: Axial fans are used in paint spray booths and other areas where air quality control is essential.

- Data Centers and Server Rooms: They help in cooling servers and electronic equipment, which is vital to prevent overheating and ensure uninterrupted operation.

- Transportation: Axial flow fans are also used in railway and subway systems for tunnel ventilation and in automotive applications for engine cooling.

- Marine Applications: On ships and in dockyards, these fans are used for engine room ventilation and controlling the air quality in enclosed spaces.

Applications of Axial Flow Fans

| Application | Direct Drive Axial Fan | Belt Drive Axial Fan | Short Cased Axial Fan |

| Industrial Ventilation | Highly suitable (efficient air movement) | Suitable (flexible airflow control) | Good for general ventilation |

| HVAC Systems | Common in large buildings (efficient airflow) | Used in larger systems (adjustable speed) | Suitable (compact and efficient) |

| Cooling Systems | Ideal for consistent cooling needs | Good for variable cooling needs | Applicable (especially if space is limited) |

| Space-Constrained Areas | Suitable (compact design) | Less suitable (larger size) | Highly suitable (very compact) |

| Harsh Environments | Less suitable (motor exposed to airstream) | More suitable (motor can be isolated) | Varies (depends on design) |

| Variable Airflow Requirements | Less flexible (fixed speed) | Highly flexible (adjustable speed) | Varies (depends on motor and drive type) |

Why Use an Axial Fan Over a Centrifugal Fan?

Choosing between axial and centrifugal fans depends on specific needs:

- Air Volume and Direction: Axial fans are preferred for applications that require moving a large volume of air over long distances. Unlike centrifugal fans, which move air at 90 degrees, axial fans pull air parallel to the axis, making them more suitable for certain applications.

- Efficiency and Speed: Axial fans are more energy efficient and capable of operating at a higher speed, making them ideal for continuous operation in demanding environments.

- Pressure Requirements: While centrifugal fans are better for higher pressure applications, axial fans are sufficient for most industrial and commercial settings requiring large air movement.

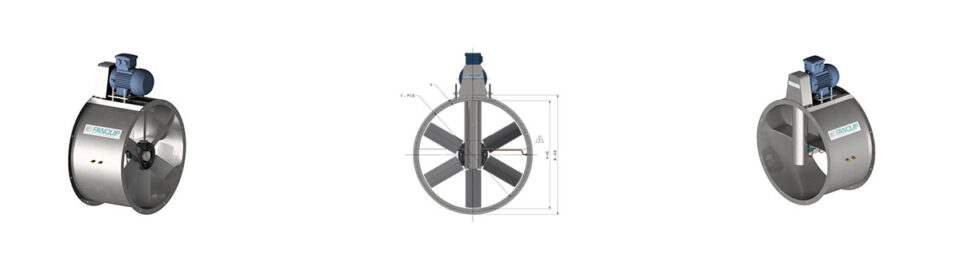

Fanquip Axial Flow Fan Range

Fanquip’s Axial Flow Fans offer robust, energy-efficient solutions for a variety of applications. These fans are an excellent choice for businesses in Australia needing to move large volumes of air, especially in challenging environments like food processing factories, warehouses, and mining operations. With their durable construction and efficient design, Fanquip’s axial fans ensure a reliable air management solution for your industrial needs.