When temperatures start to rise, it can be challenging to keep your warehouse or workplace cool. Many companies rely on air conditioning to keep indoor temperatures comfortable during summer, however, it can be a costly long-term solution. An effective cooling and heat extraction solution can be the difference between extreme heat and a cool congenial workplace.

Maintaining cool and comfortable working conditions can help improve employee satisfaction and productivity. Working in extreme heat can be hazardous, as workers become lethargic and unfocused [1]. Heat stress can be monitored through a heat stress calculator which takes into consideration the temperature, humidity, task complexity and acclimatisation [2]. Smelting, food processing and manufacturing industries may have risk assessments in place to ensure the safety of their employees. Identify and manage heat stress by assessing the air temperatures, workplace conditions, job requirements and individual worker attributes. Cooling should be a priority at your workplace as exposure to extreme heat or working in hot environments can result in occupational illnesses and injuries [4].

There are tactics and strategies to help cool down your workplace or warehouse in both industrial and commercial settings. The most effective and efficient solution utilises cooling and extraction fans in conjunction to push cold air around the room and extract hot air rising to the roof. Keep reading to learn more about strategies and products aimed to keep your warehouse or industrial facility cool this summer.

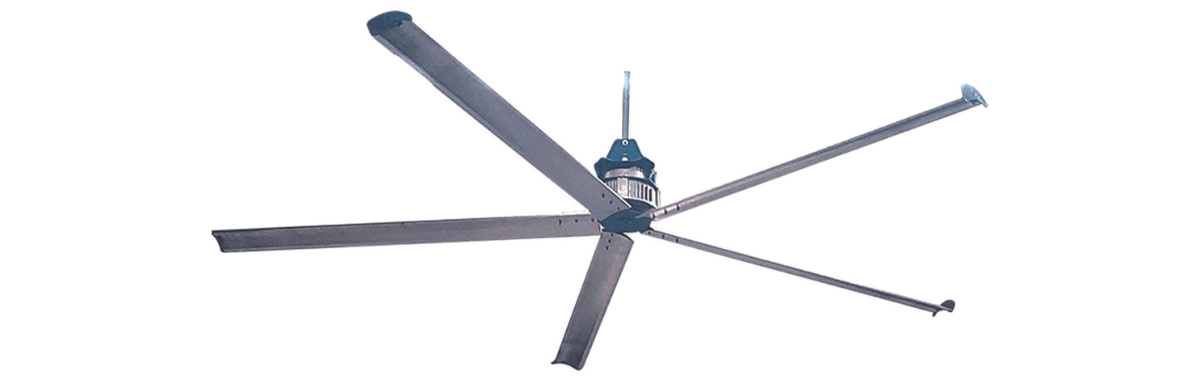

HVLS Industrial Fans

High-volume, low-speed (HVLS) industrial fans can be deployed to efficiently and effectively circulate large volumes of air throughout your workplace or industrial facility. Giant fans are recommended for cooling large areas due to their widespread coverage with fans sizes available up to 7m in diameter. This energy-efficient industrial cooling solution runs at a low cost in with an IP65 water and dust-resistant brushless motor and integrated inverter with remote controls.

Distributing and pushing cool air around your warehouse or industrial facility can help support comfortable indoor temperatures. Giant fans are a fantastic way to circulate air and when coupled with a ventilation system you can maximise their effectiveness by extracting hot air from the roof. Fanquip’s Giant Fans are suitable for both summer and winter, with a simple adjustment of the blade direction and the pitch of the impeller to either blow air downwards or to bring air up towards the roof. Direct your fan blades to push down cool air during summer, while you may want to push air upwards to aid heat stratification during winter.

Fanquip proudly manufactures Giant Fans in Australia utilising superior technology with a 3-year fan inverter life and a 50,000-hour warranty. As your HVLS fan moves around large volumes of air, it can also give your existing HVAC system a boost, if you already have one installed. This solution provides high energy efficiency with low consumption, designed for industrial, commercial and agricultural installations to ensure the comfort of staff, clients and livestock.

Industrial Roof Fans

Roof fans or extraction systems are designed to exhaust trapped heat and stifling air from the ceiling or roof area. This helps to cool the warehouse or facility whilst also improving indoor air quality. Removing airborne contaminants and hot air helps to create a comfortable and safe work environment for all. Some workplace facilities may require consistent regulation of temperatures, particularly for the food processing industry.

When deciding the right extraction solution for your workplace, a simple calculation of the room size and application is needed. This will help you estimate the capacity range in cubic metres per hour (m3/hr) whilst confirming the fan size or quantity needed for your space. At Fanquip, our ventilation specialists will come to your workplace, take detailed notes of your requirements, inspect the area and formulate a solution for your needs and budget.

Fanquip offers three types of industrial roof fans including curb-based hooded, profile-base hooded and vertical discharge roof fans. All fans offer a versatile application as either an exhaust or air supply fan which has been designed for demanding applications and the Australian climate. Strategically place your roof fan away from the main opening of a warehouse, workshop, manufacturing facility or processing plant to create an airflow drawn in through the main opening. Discover Fanquip’s full range and comparison of industrial roof fans today.

Cool your workplace and extract heat

Cooling solutions such as industrial fans or HVAC systems can be used in conjunction with exhaust or extraction fans to improve their overall effectiveness. Installing extraction fans helps to expel stifling air as it rises, allowing cool air to circulate throughout the premises. It also reduces humidity levels while reducing the strain on any cooling systems you may have installed.

In summer, industrial ceiling fans are a cost-effective solution in comparison to the running costs of a HVAC system. Circulating cool air reduces the need for air conditioning, especially when coupled with an extraction system to expel balmy air from the facility. Giant fans can reduce perceived temperatures by up to 8 degrees with added reductions in levels when hot air is discharged.

The animation below depicts how industrial fans can be used in conjunction with extraction fans. Giant industrial fans push down large volumes of cool air, with warm air rising to the top of room and expelled to the external environment via roof fans.

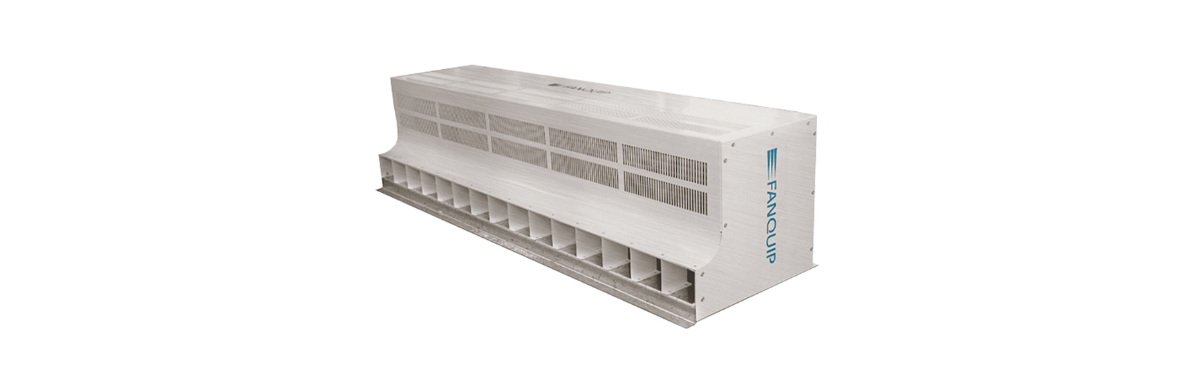

Air Curtains for food processing

Air curtains are utilised within the food processing industry to help regulate indoor temperatures. Typically installed on a door or opening, air curtains create an invisible air barrier to maintain indoor air quality and restrict the outflow of internal air. Regulate indoor temperatures and prevent external contaminants by using an air curtain, allowing the environment’s cool air to stay in while forcing stifling air to stay out.

Fanquip’s range of air curtains are available in 900mm – 1500mm with free air volume outputs of 850 – 2200 litres per second. Proudly manufactured in Australia from heavy-duty stainless steel, IP56 washdown duty motor, meeting AQIS (Australian Quarantine Inspection Service) requirements of 8 metres/second at 900mm above floor level. Air curtains prioritise customer and employee comfort as they regulate the air temperatures and reduce the strain on existing cooling systems, minimising energy costs.

Follow Fanquip’s strategies and solutions to effectively manage indoor heat levels in both commercial and industrial settings during summer. Stay on top of the heat and keep productivity levels high for all personnel throughout the warmer months.

If you would like a custom solution or ventilation audit for your warehouse or workplace, please contact us online or call 1300 224 308

References

- https://www.safeworkaustralia.gov.au/system/files/documents/1902/guide_for_managing_the_risks_of_working_in_heat_1.pdf

- https://fswqap.worksafe.qld.gov.au/etools/views/calc/heatStress.xhtml

- https://reader.elsevier.com/reader/sd/pii/S0378778821006034

- https://www.cdc.gov/niosh/topics/heatstress/default.html