- Cooling (10) ▼

- Extraction (16) ▼

- Filtration (7) ▼

- Heating (1) ▼

- Accessories (14) ▼

- Add Ons (11)Unsure what products are right for your ventilation needs? Product Finder

- Add Ons (11)

Options▼

- 060L/s (2)

- 060Pa (2)

- 2 speed motor (1)

- 5m length (1)

- Acoustic design for noise reduction (1)

- Additional lengths of ducting available (3)

- Air Volume - 236L/s to 4 (2)

- Aluminium adjustable pitch blades (11)

- Aluminium or stainless steel casings (9)

- Available without fan/motor as a relief vent (2)

- Belt driven or bifurcated design (2)

- Bifurcated casing design (2)

- Compressed air powered (4)

- Corporate colours and labeled (1)

- Custom arrangements/specifications (2)

- Exd (16)

- ExnA (16)

- Extd (16)

- Extended lead and control switch (2)

- Filters fitted for clean air supply (1)

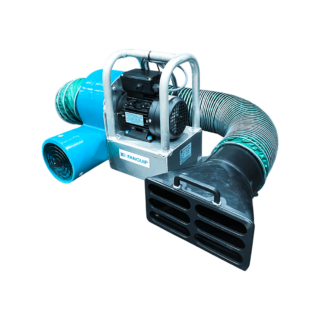

- Flexible ducting (1)

- Flexible ducting - 300mm dia (1)

- Front safety guard (1)

- Full range of accessories including angle rings (3)

- Galvanised/stainless steel (2)

- Hazardous location rated - Exe (16)

- Hazardous locations (flameproof) (2)

- Hot dip galvanised finish (2)

- Hydroblast misting kit attachment (1)

- Inlet and outlet finger guards (3)

- Intrinsically safe motors (2)

- IP56 or IP66 motor (12)

- IP66 Motor (415V models only) (4)

- Motor Power - 1.1kW to 7.5kW (2)

- Motorised damper (1)

- mounting feet and inlet cones (3)

- Outlet finger guard (1)

- Powder coated finish (4)

- Sizes: 300mm to 600mm diameter (2)

- Smoke spill rated (3)

- Stainless steel casing (2)

- Stainless steel construction (5)

- Static Pressure 284Pa to 4 (2)

- Straightening vanes (1)

- Supply Air version available (1)

- Upstand for fan mounting (3)

- Wall/ceiling mounting bracket (1)

- Wide range of colour options available (2)

Poles▼

From: $902 Exc. GST

Select options This product has multiple variants. The options may be chosen on the product page

From: $7,169 Exc. GST

Select options This product has multiple variants. The options may be chosen on the product page

From: $2,827 Exc. GST

Select options This product has multiple variants. The options may be chosen on the product page

From: $4,461 Exc. GST

Select options This product has multiple variants. The options may be chosen on the product page